Safety should never be an afterthought when it comes to inflatable entertainment equipment. With children’s laughter filling bounce houses and slides across playgrounds worldwide, ensuring their protection becomes paramount. This is where EN14960, the European safety standard for inflatable play equipment, plays a crucial role in safeguarding young users while maintaining the joy these attractions bring.

What is EN14960?

EN14960 represents the gold standard for inflatable play equipment safety in Europe and increasingly worldwide. This comprehensive standard applies to inflatable play equipment intended for use by children fourteen years and under, covering equipment where the primary activities are bouncing and sliding. The current version, EN14960:2019, replaced the earlier 2006 standard with enhanced safety requirements based on extensive research and real-world incident data.

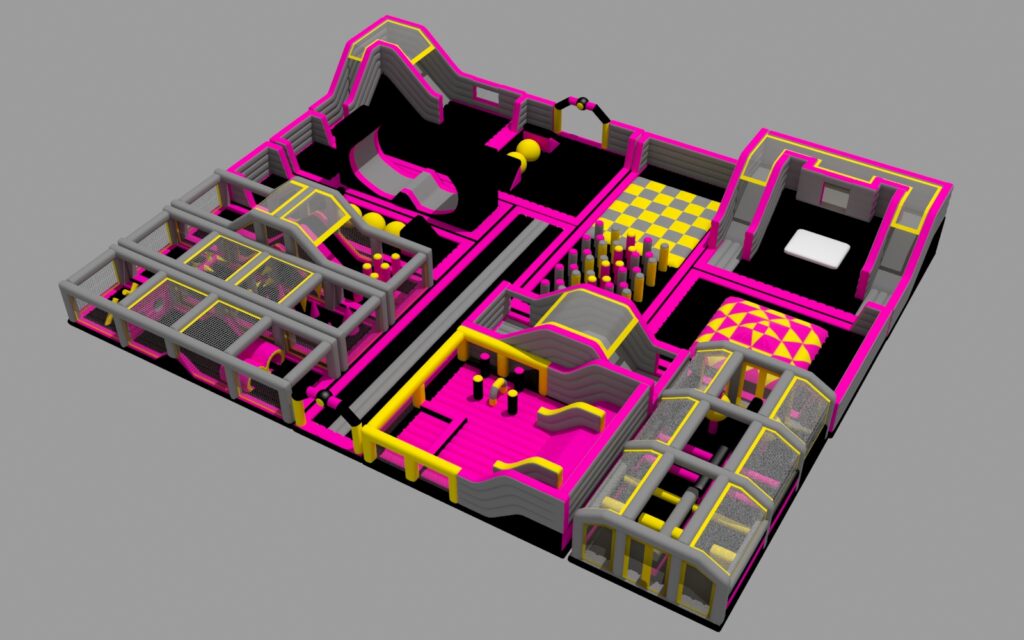

The standard encompasses various inflatable attractions including bounce houses, inflatable slides, obstacle courses, and combo units. However, it specifically excludes water-based inflatables, domestic toys, air-supported buildings, and specialized equipment designed for rescue purposes.

Core Safety Requirements Under EN14960

The EN14960 standard establishes rigorous design and construction criteria that manufacturers must follow to ensure user safety.

Design and Construction Standards

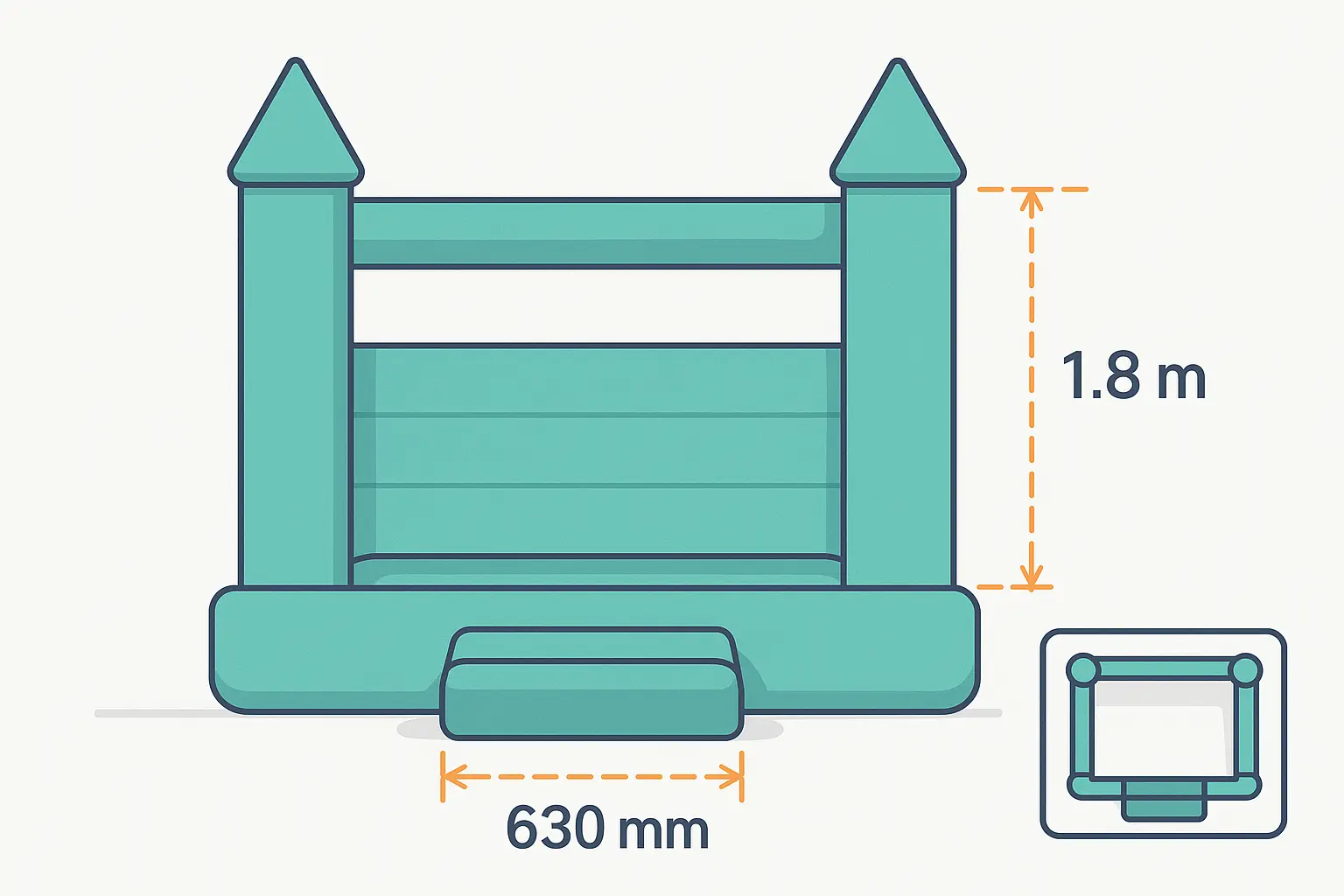

For bounce houses and enclosed structures, the standard mandates that walls must be at least 1.8 meters high to prevent users from accidentally jumping over them. This requirement addresses one of the most common safety concerns in inflatable play equipment.

Bounce houses must feature three enclosed walls with only one open entrance side. The entrance height cannot exceed 630mm from the ground, and operators must provide cushioned crash mats at exit points to protect users who might fall.

The standard also prohibits sharp edges or protrusions that could cause injury. All seams and joints must meet specific strength requirements to ensure structural integrity during use. These construction details might seem minor, but they represent the difference between safe play and potential accidents.

Manufacturing Quality Controls

EN14960 requires comprehensive material testing protocols that evaluate fabric strength, seam durability, and overall structural stability. Manufacturers must demonstrate that their products can withstand expected forces during normal use and emergency situations.

The standard also specifies blower compatibility requirements, ensuring that inflation systems provide consistent air pressure while incorporating safety mechanisms for power failures. Quality assurance processes must be documented and verifiable, creating accountability throughout the manufacturing chain.

Testing and Certification Process

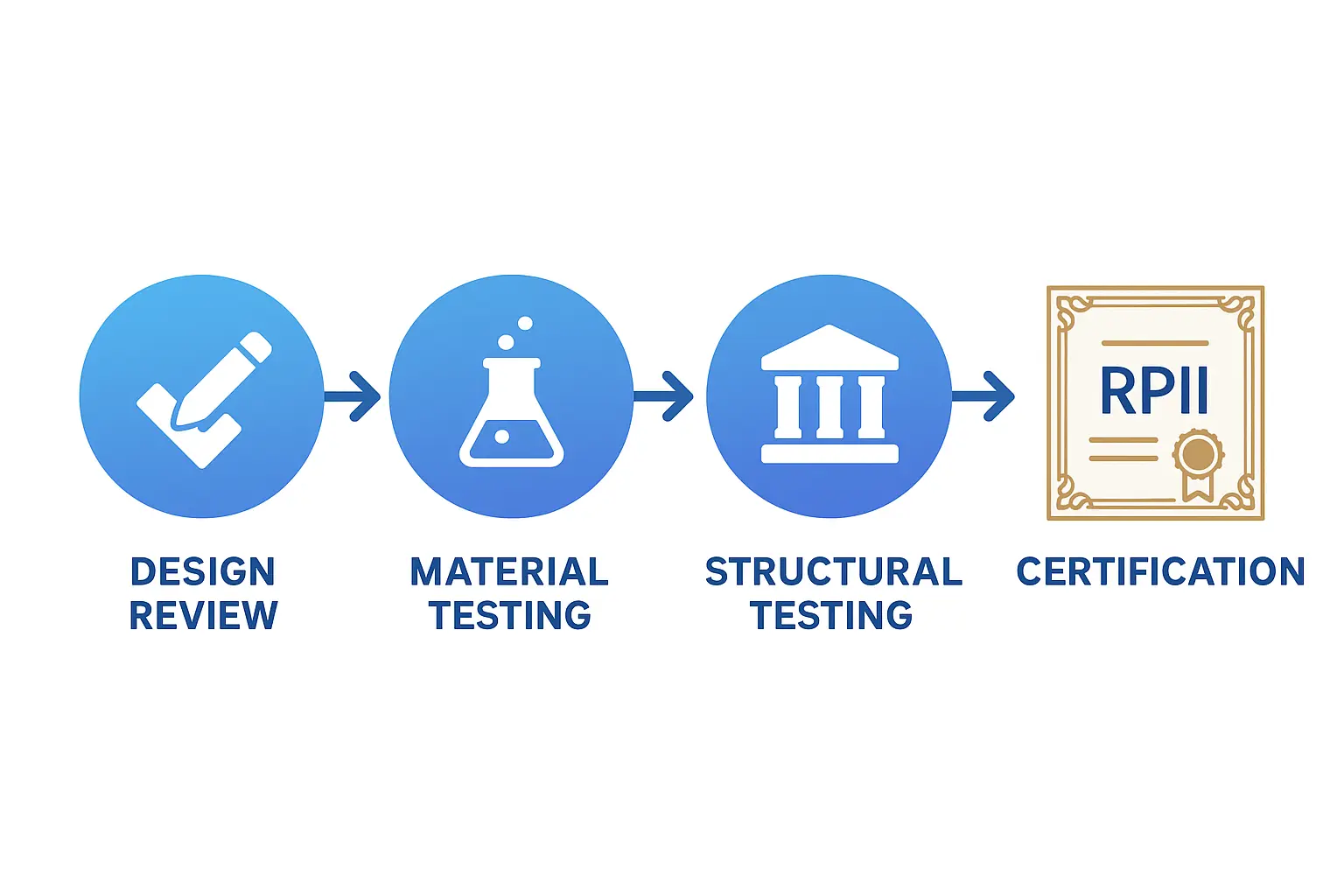

Achieving EN14960 certification requires products to undergo rigorous evaluation by qualified inspection bodies. The certification process involves detailed assessment of design compliance, material strength testing, and verification of safety features.

Testing procedures examine structural stability under various load conditions, evaluating how equipment responds to different usage scenarios. Inspectors verify that safety barriers, entrance designs, and anchoring systems meet specification requirements.

The RPII (Recreational Power Industries International) certification represents one recognized form of EN14960 compliance verification. Each certified product receives a unique, traceable certificate that facilitates market entry, particularly in European markets.

Importantly, EN14960 compliance isn’t a one-time achievement. The standard requires regular reassessment to ensure continued safety performance as equipment ages and usage patterns change.

Benefits for Manufacturers and Consumers

For Manufacturers

EN14960 certification opens doors to European and other international markets where safety compliance is mandatory. This certification provides significant competitive advantages in a crowded marketplace, as buyers increasingly prioritize safety credentials when making purchasing decisions.

Beyond market access, certification enhances brand credibility and demonstrates commitment to user safety. This reputation building proves invaluable for long-term business success, as safety-conscious customers tend to become loyal, repeat buyers.

The standard also provides manufacturers with clear design guidelines, reducing liability risks and potential legal complications. When accidents do occur, demonstrating compliance with recognized safety standards can provide crucial legal protection.

For Consumers and Operators

For parents, event planners, and facility operators, EN14960 certification provides peace of mind that equipment meets rigorous safety standards. This certification is particularly important for insurance coverage, as many providers require safety standard compliance for coverage eligibility.

Operators benefit from reduced accident risks, which translate to lower insurance premiums, fewer liability concerns, and enhanced reputation within their communities. When equipment meets EN14960 standards, operators can confidently promote their commitment to safety, attracting safety-conscious customers.

Impact on the Global Inflatable Industry

While EN14960 originated as a European standard, its influence extends far beyond EU borders. Many manufacturers worldwide now design products to meet these requirements, recognizing that EN14960 compliance opens international market opportunities.

Other regions have developed comparable standards, such as AS3533.4 in Australia, but EN14960 remains the most widely recognized benchmark globally. This standardization benefits the entire industry by establishing consistent safety expectations and manufacturing practices.

The standard continues evolving based on incident data and technological advances. Manufacturers who stay ahead of these developments position themselves advantageously as safety requirements become more stringent over time.

Choosing EN14960-Certified Equipment

When selecting inflatable equipment, asking the right questions ensures you receive genuinely compliant products. Request documentation proving certification, including certificate numbers and testing dates. Verify that certificates come from recognized inspection bodies rather than self-declarations.

Working with established manufacturers who understand EN14960 requirements provides additional assurance. Companies like Minye Fun, with extensive experience in certified manufacturing, can guide customers through compliance requirements while delivering products that exceed safety expectations.

Consider the total cost of ownership, not just initial purchase price. Certified equipment may cost more upfront but typically offers superior durability, lower maintenance requirements, and reduced liability risks that provide better long-term value.

Ask about ongoing support, including maintenance guidelines, repair services, and recertification assistance. Reputable manufacturers stand behind their products with comprehensive support programs that help maintain safety compliance throughout equipment lifecycles.

Conclusion

EN14960 represents more than regulatory compliance – it embodies the industry’s commitment to keeping children safe while preserving the joy that inflatable attractions provide. As safety awareness grows among consumers and operators, this standard becomes increasingly valuable for distinguishing quality manufacturers from those cutting corners.

Understanding EN14960 requirements helps everyone in the inflatable industry make informed decisions that prioritize safety without sacrificing fun. Whether you’re a manufacturer, operator, or end user, investing in certified equipment demonstrates responsibility toward the children who trust us with their entertainment and safety.

The inflatable industry continues growing worldwide, bringing smiles to millions of children annually. By embracing standards like EN14960, we ensure this growth happens safely, sustainably, and with the highest regard for those we serve.

For manufacturers seeking EN14960 certification or customers requiring certified equipment, partnering with experienced professionals makes the difference between compliance and confusion. The investment in safety standards isn’t just good business – it’s the right thing to do for the children who make our industry meaningful.