The commercial inflatable industry has experienced remarkable growth, with market projections showing continued expansion through 2025. Whether you’re operating bounce house rentals, water parks, or large-scale entertainment venues, your business success fundamentally depends on one critical factor: material quality.

When customers entrust their safety and enjoyment to your inflatables, the difference between premium and standard materials can determine your profitability, liability exposure, and long-term reputation. Understanding why high-quality PVC tarpaulin matters isn’t just about product knowledge—it’s about protecting your investment and ensuring sustainable business growth.

Understanding PVC Tarpaulin Construction

PVC tarpaulin represents the gold standard for commercial inflatables due to its sophisticated multi-layer construction. The foundation begins with a high-tensile polyester fabric base, typically woven from 1000D polyester threads that provide exceptional structural integrity. This base fabric undergoes a precise double-sided PVC coating process, where liquid PVC compounds are applied under controlled temperature and pressure conditions.

The standard thickness for commercial applications measures 0.55mm, though premium versions can reach 0.7mm for heavy-duty installations. This thickness specification isn’t arbitrary—it represents the optimal balance between flexibility for inflation and durability for sustained use. The manufacturing process includes heat-sealing techniques that create molecular bonds between PVC layers, resulting in virtually seamless construction that resists delamination over time.

Quality manufacturers implement strict temperature controls during production, ensuring consistent coating thickness and proper adhesion. This attention to manufacturing detail directly translates to field performance, where properly constructed tarpaulin maintains its integrity through thousands of inflation cycles.

Key Quality Indicators for Commercial Applications

Professional operators must evaluate several critical performance metrics when selecting PVC tarpaulin. Tensile strength ratings indicate how much force the material can withstand before tearing, with commercial-grade tarpaulin typically exceeding 2000N per 5cm strip. Tear resistance, measured through standardized testing, determines how well the material contains damage when punctures occur.

UV protection becomes crucial for outdoor installations, where prolonged sunlight exposure can degrade inferior materials within months. High-quality PVC tarpaulin incorporates UV stabilizers that maintain color integrity and structural properties for years, not seasons. Fire retardant properties ensure compliance with safety regulations, while lead-free formulations meet increasingly stringent environmental standards.

Modern commercial tarpaulin also features enhanced cold crack resistance, maintaining flexibility in temperatures as low as -30°C. This specification proves essential for operators in northern climates or those providing year-round services. Water resistance ratings determine performance in wet conditions, particularly important for water slides and pool applications where chlorine exposure adds additional stress.

Business Impact of Material Quality

The financial implications of material selection extend far beyond initial purchase costs. Premium PVC tarpaulin typically lasts 3-5 times longer than economy alternatives, dramatically reducing replacement frequency and associated labor costs. When you factor in lost revenue during equipment downtime, the economics overwhelmingly favor quality materials.

Safety compliance represents another critical business consideration. High-quality tarpaulin meets or exceeds EN14960-2013 standards, reducing liability exposure and insurance costs. Many operators discover that premium materials actually lower their insurance premiums due to improved safety profiles and reduced claim histories.

Customer experience directly correlates with material quality. Vibrant colors that resist fading, surfaces that remain comfortable during extended play, and equipment that maintains its appearance throughout busy seasons all contribute to customer satisfaction and repeat bookings. Word-of-mouth recommendations often hinge on these quality perceptions.

Maintenance requirements also differ significantly between quality levels. Premium tarpaulin resists staining, cleans more easily, and maintains structural integrity through aggressive cleaning protocols. This durability reduces labor costs while extending equipment life cycles.

Performance Comparison: Premium vs. Standard Materials

The performance gap between premium and standard PVC tarpaulin becomes evident under real-world operating conditions. Puncture resistance testing reveals that premium materials often withstand 40-60% more force before failure, crucial when dealing with excited children wearing shoes or carrying sharp objects.

Color retention presents another stark contrast. While standard materials may show noticeable fading within six months of outdoor use, premium tarpaulin maintains vibrant appearance for multiple seasons. This visual quality directly impacts marketing effectiveness and customer perceptions of value.

Structural integrity under continuous use varies dramatically. Premium materials maintain consistent air pressure with minimal leakage, while inferior alternatives often require frequent re-inflation. The energy costs alone can justify premium material selection over a single operating season.

Temperature tolerance ranges showcase another advantage. Premium PVC tarpaulin functions reliably from -30°C to 70°C, while standard materials may become brittle in cold conditions or soften excessively in heat. This expanded operating range translates to longer seasons and more revenue opportunities.

Application-Specific Considerations

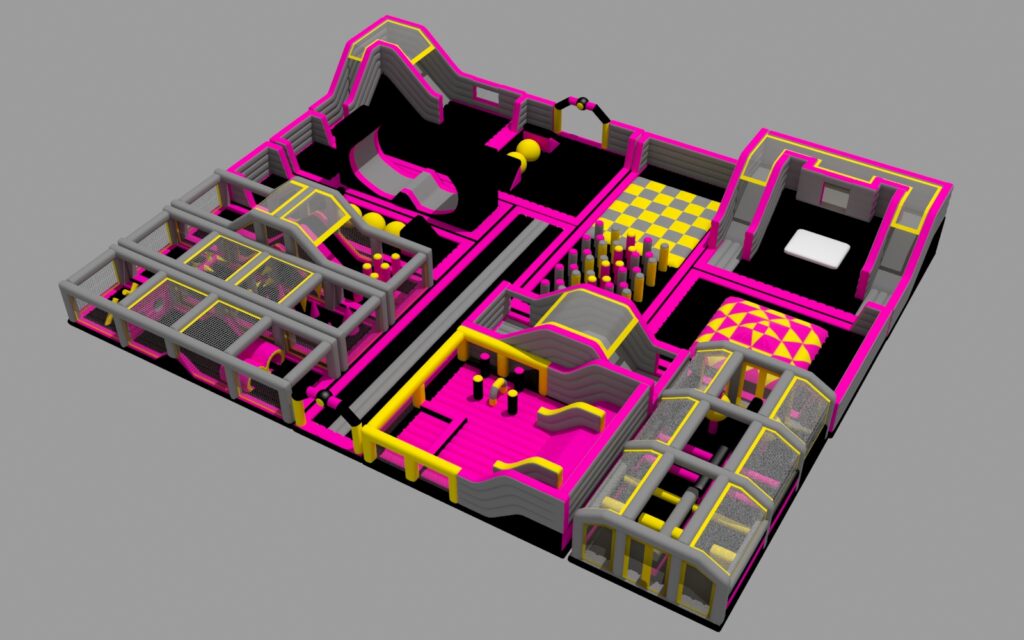

Different inflatable applications demand specific material characteristics. Bounce houses and play structures require excellent abrasion resistance due to constant contact with users. The material must maintain structural integrity while providing appropriate cushioning properties that ensure user safety without compromising bounce quality.

Water park inflatables face unique challenges including chlorine exposure, constant moisture, and UV radiation. Premium tarpaulin formulated for aquatic applications includes specialized additives that resist chemical degradation while maintaining slip-resistant surface properties.

Large-scale commercial installations demand materials that perform consistently across extensive surface areas. Thermal expansion and contraction cycles stress materials differently in massive structures compared to smaller units. Premium tarpaulin maintains uniform performance characteristics regardless of installation size.

Indoor versus outdoor deployment creates different material requirements. Indoor applications may prioritize fire retardant properties and low-emission formulations, while outdoor units need maximum UV protection and weather resistance. Understanding these distinctions helps operators make informed material selections.

Quality Assessment Guidelines

Proper material evaluation requires systematic testing and documentation. Thickness measurements should be verified using precision calipers, ensuring consistency across the entire material surface. Reputable suppliers provide detailed specifications including tensile strength, tear resistance, and UV protection ratings.

Certification requirements vary by jurisdiction, but EN14960-2013 represents the international standard for inflatable play equipment. This certification covers material properties, construction techniques, and safety features. Operators should verify that materials meet or exceed applicable standards before making purchasing decisions.

Supplier evaluation involves examining manufacturing processes, quality control procedures, and testing protocols. Established manufacturers maintain detailed records of material properties and provide comprehensive warranties that demonstrate confidence in their products.

Testing procedures for new installations should include thorough inspections of seam integrity, surface consistency, and performance under load. Documentation of these tests provides valuable baseline data for tracking long-term performance and planning maintenance schedules.

Cost-Benefit Analysis

The initial investment in premium PVC tarpaulin typically costs 30-50% more than standard alternatives, but this premium pays dividends through extended service life and reduced operating costs. When analyzing total cost of ownership over a typical 5-7 year operational period, premium materials often prove less expensive per year of service.

Insurance and liability considerations add another layer to the financial equation. Many insurance providers offer reduced premiums for operators using certified premium materials, recognizing the lower risk profile associated with quality equipment. The potential savings in insurance costs alone may offset the material premium.

Customer satisfaction metrics improve measurably with quality materials. Repeat booking rates, positive reviews, and referral generation all correlate with equipment quality. These factors directly impact revenue generation and business growth potential.

Competitive advantage through quality becomes increasingly important as the market matures. Operators using premium materials can command higher rental rates while experiencing lower maintenance costs and extended equipment life. This combination creates sustainable competitive advantages that compound over time.

Expert Recommendations

Industry professionals consistently recommend minimum quality standards for commercial applications. The 0.55mm thickness represents the baseline for commercial use, with heavier-duty applications benefiting from 0.7mm materials. Never compromise on core quality specifications to achieve lower pricing.

Maintenance best practices extend material life and preserve investment value. Regular cleaning with appropriate solutions, proper storage techniques, and systematic inspection protocols all contribute to maximizing return on material investments. Preventive maintenance costs significantly less than premature replacement.

Supplier selection criteria should emphasize manufacturing experience, quality certifications, and comprehensive warranty coverage. Established suppliers like Minye Fun understand the unique demands of commercial applications and provide materials specifically engineered for sustained use. Their expertise in commercial inflatable manufacturing ensures material specifications align with real-world operating requirements.

Quality assurance protocols should include incoming material inspection, periodic testing during use, and detailed maintenance records. These procedures help identify potential issues before they impact operations while providing documentation for warranty claims and insurance purposes.

Maximizing Your Investment Return

Success in the commercial inflatable industry depends on making informed decisions that balance initial costs with long-term performance. High-quality PVC tarpaulin represents more than a material choice—it’s a strategic business decision that impacts profitability, safety, and customer satisfaction.

The evidence overwhelmingly supports investing in premium materials. Extended service life, reduced maintenance costs, improved safety compliance, and enhanced customer satisfaction all contribute to superior business outcomes. When you consider the total cost of ownership and revenue potential, quality materials consistently deliver better returns.

For operators serious about building sustainable businesses, the choice becomes clear. Premium PVC tarpaulin provides the foundation for reliable operations, satisfied customers, and profitable growth. The initial investment pays dividends through years of dependable performance and competitive advantage.

Contact experienced manufacturers like Minye Fun for expert guidance on material selection and customization options that meet your specific operational requirements. Their extensive experience in commercial inflatable manufacturing ensures you receive materials engineered for success in demanding commercial applications.