The roar of gas engines has long been synonymous with go-kart racing, but a quieter revolution is taking the track by storm. Electric go-karts are rapidly becoming the gold standard for racing enthusiasts, and at the core of this transformation lies one critical component: the battery. It’s not just about going green—it’s about delivering superior performance, enhanced safety, and a more exhilarating racing experience.

Understanding what powers your kart isn’t just technical knowledge; it’s the key to appreciating why electric go-karts are changing the game. Let’s dive deep into the battery technology that makes modern electric racing possible and explore the comprehensive safety features that keep drivers protected lap after lap.

Battery Technology Fundamentals

Why Lithium-Ion Dominates Electric Racing

When it comes to powering electric go-karts, lithium-ion batteries have become the undisputed champion. Unlike traditional lead-acid batteries that powered early electric vehicles, lithium-ion technology offers a superior power-to-weight ratio that’s essential for racing performance. These batteries pack significantly more energy into a smaller, lighter package, which translates directly to better acceleration and handling on the track.

The chemistry behind lithium-ion batteries allows for rapid energy discharge without the voltage drop that plagued older battery technologies. This means consistent power delivery from the first lap to the last, eliminating the frustrating power fade that can occur with inferior battery systems. The technology relies on lithium ions moving between positive and negative electrodes through an electrolyte solution, creating a reliable and repeatable energy flow that racing demands.

Performance Specifications That Matter

Modern electric go-kart batteries typically operate at voltages ranging from 48V to 72V, with capacities measured in amp-hours that determine how long you can race before needing a recharge. Higher voltage systems deliver more power to the motors, enabling faster acceleration and higher top speeds. The capacity, meanwhile, determines your runtime—critical for extended racing sessions or commercial track operations.

At Minye Fun, our battery systems are engineered specifically for the demands of competitive racing. We’ve optimized the balance between power output and longevity, ensuring that drivers experience consistent performance whether they’re on their first lap or their fiftieth. Our batteries deliver instant maximum torque, providing that heart-pounding acceleration the moment you press the pedal.

Charging technology has evolved dramatically as well. Modern fast-charging systems can replenish a depleted battery to 80% capacity in under two hours, with full charges typically completing in three to four hours. This rapid turnaround means minimal downtime between racing sessions, keeping the excitement going throughout the day.

Performance Advantages of Advanced Battery Systems

Instant Torque: The Electric Advantage

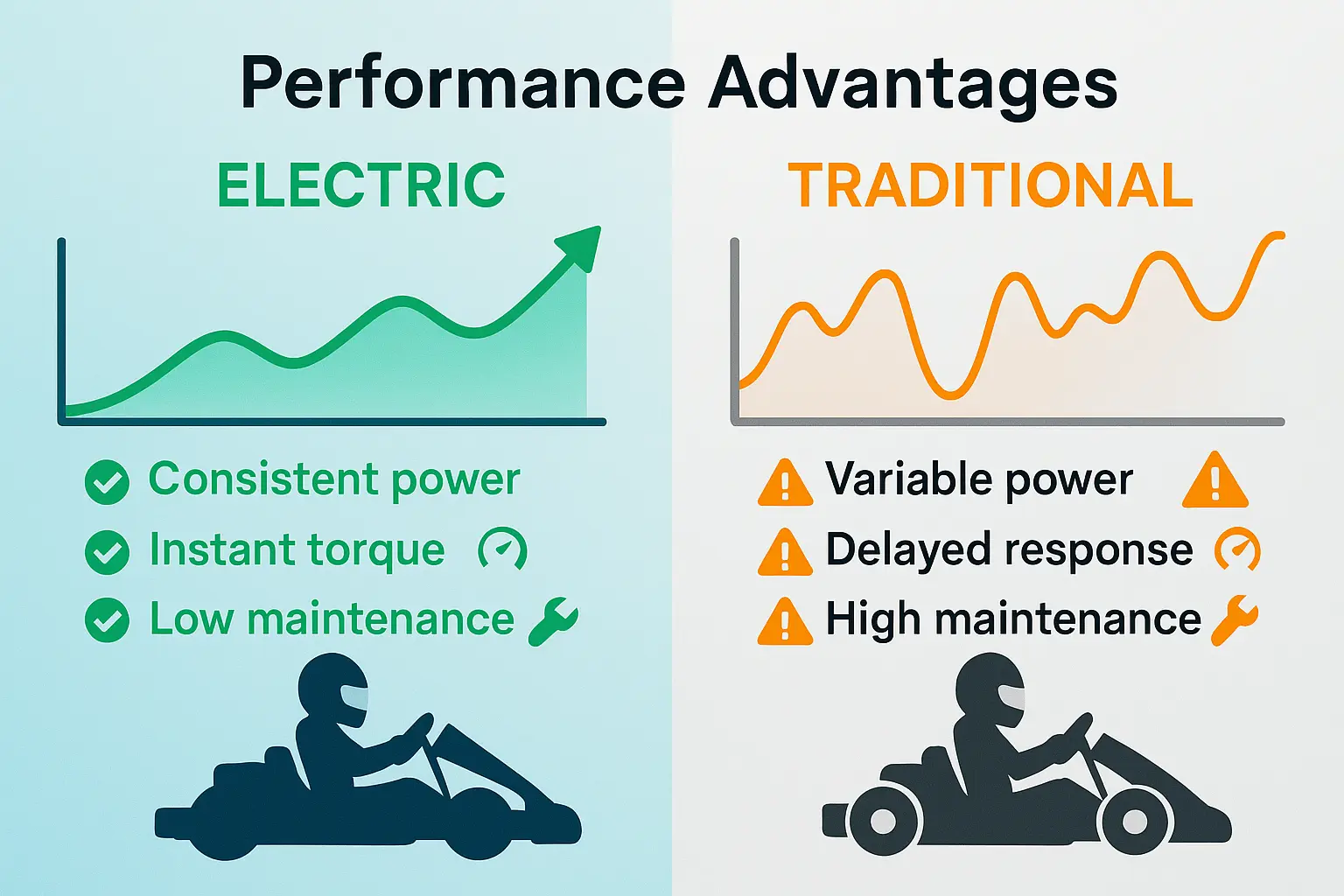

One of the most thrilling aspects of electric go-karts is the instantaneous torque delivery that batteries enable. Unlike gas engines that need to build RPMs to reach peak power, electric motors powered by lithium-ion batteries deliver maximum torque from a standstill. The result? Explosive acceleration that pins you to your seat and gives you the jump on competitors right out of the gate.

This immediate power response creates a more intuitive driving experience. There’s no lag between throttle input and acceleration, making the kart feel like an extension of your own reflexes. For competitive racers, this split-second advantage can mean the difference between leading into the first turn or playing catchup for the rest of the race.

The consistency of power delivery throughout the battery’s discharge cycle is equally important. Unlike combustion engines that experience power fluctuations based on fuel levels and engine temperature, electric systems maintain steady performance until the battery reaches very low charge levels. This predictability allows drivers to push harder with confidence, knowing their kart will respond the same way on the last lap as it did on the first.

Optimized Weight Distribution and Handling

Battery placement isn’t arbitrary in well-designed electric go-karts—it’s a carefully calculated decision that affects every aspect of handling. By positioning battery packs low and centrally in the chassis, engineers lower the center of gravity dramatically compared to traditional karts. This translates to improved cornering stability and reduced body roll through tight turns.

The weight distribution also affects traction. With batteries positioned near the rear axle, electric karts achieve optimal weight transfer during acceleration, putting power to the ground more effectively. This is particularly noticeable when exiting corners, where the combination of instant torque and ideal weight placement allows for aggressive throttle application without breaking traction.

Modern battery pack designs are remarkably compact, allowing for creative chassis configurations that would be impossible with bulky gas engines. This flexibility has enabled manufacturers to create karts with lower profiles and more aerodynamic shapes, further enhancing performance at higher speeds.

Environmental and Operational Benefits

The environmental advantages of battery-powered go-karts extend beyond the obvious zero-emissions operation during races. These systems eliminate the need for petroleum-based fuels, reducing the carbon footprint associated with transportation and storage of gasoline. For indoor karting facilities, this means no exhaust fumes to ventilate, creating a healthier environment for both racers and spectators.

Noise reduction is another significant benefit that’s often underappreciated until experienced firsthand. Electric go-karts operate at a fraction of the decibel level of their gas counterparts, making communication possible without shouting and reducing the need for hearing protection. This quieter operation opens up racing opportunities in urban areas and indoor venues where noise restrictions would prohibit traditional gas-powered karts.

The operational simplicity of electric systems also deserves mention. There are no oil changes, spark plug replacements, or carburetor adjustments required. Battery-powered karts need minimal routine maintenance compared to combustion engines, reducing downtime and long-term operating costs. This reliability means more time racing and less time wrenching.

Comprehensive Safety Features and Protocols

Intelligent Battery Management Systems

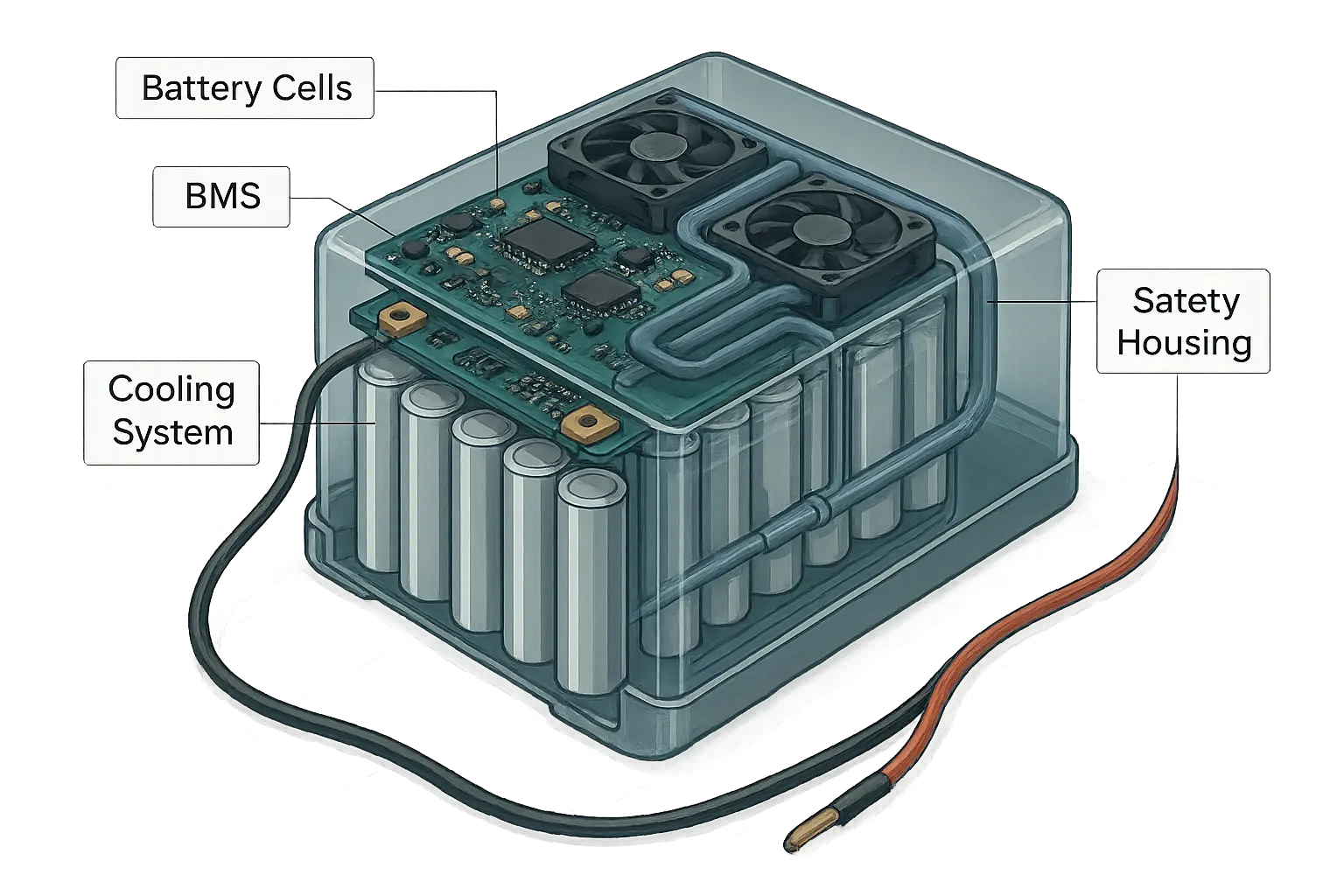

The Battery Management System, or BMS, is the unsung hero of electric go-kart safety. This sophisticated electronic brain constantly monitors every critical parameter of the battery pack, making thousands of calculations per second to ensure safe operation. Think of it as a vigilant guardian that never sleeps, always watching for potential problems before they become dangerous.

Temperature monitoring is one of the BMS’s most critical functions. Lithium-ion batteries perform best within specific temperature ranges, and operating outside these parameters can reduce performance or, in extreme cases, pose safety risks. The BMS continuously tracks the temperature of individual cells within the battery pack, activating cooling systems when needed and limiting power output if temperatures approach concerning levels.

Overcharge protection prevents the battery from accepting more energy than it can safely store. When charging, the BMS communicates with the charging system to regulate current flow, tapering it off as the battery approaches full capacity. This precision charging extends battery life significantly while eliminating the risks associated with overcharging.

Short-circuit protection is equally vital. In the unlikely event of a wiring fault or component failure that creates an electrical short, the BMS can detect the abnormal current flow in milliseconds and disconnect the battery from the circuit. This rapid response prevents potential fires or damage to electrical components.

Cell balancing is a more subtle but crucial function the BMS performs during every charge cycle. Not all cells in a battery pack age at exactly the same rate, and slight variations in capacity can develop over time. The BMS ensures that each cell reaches the same voltage level during charging, maximizing overall pack capacity and extending the lifespan of the entire system.

Physical Protection and Safety Design

The battery pack itself is housed in a rugged, impact-resistant enclosure designed to withstand the rigors of racing. These casings are typically constructed from high-strength composites or reinforced plastics that can absorb significant impacts without compromising the battery cells inside. In the event of a collision, the protective housing acts as a first line of defense, distributing impact forces across the structure rather than transmitting them directly to the sensitive battery components.

Mounting systems secure the battery pack rigidly to the kart’s chassis using vibration-dampening hardware. This serves two purposes: it prevents the battery from shifting during aggressive cornering or impacts, which could damage electrical connections, and it reduces the transmission of vibration to the battery cells themselves, extending their operational life.

Emergency disconnect features provide an additional safety layer. Accessible emergency shutoff switches allow track marshals or drivers to immediately cut all power from the battery to the motor system in case of an incident. Some advanced systems include automatic disconnects that trigger during severe impacts, removing power before human intervention is even possible.

Waterproofing and dust sealing protect the battery from environmental hazards. Racing environments can be harsh, with dirt, moisture, and debris constantly present. Quality battery enclosures feature sealed designs with gaskets and coatings that prevent water intrusion and keep contaminants away from electrical connections. This protection ensures reliable operation in various weather conditions and track environments.

Maintenance and Inspection Protocols

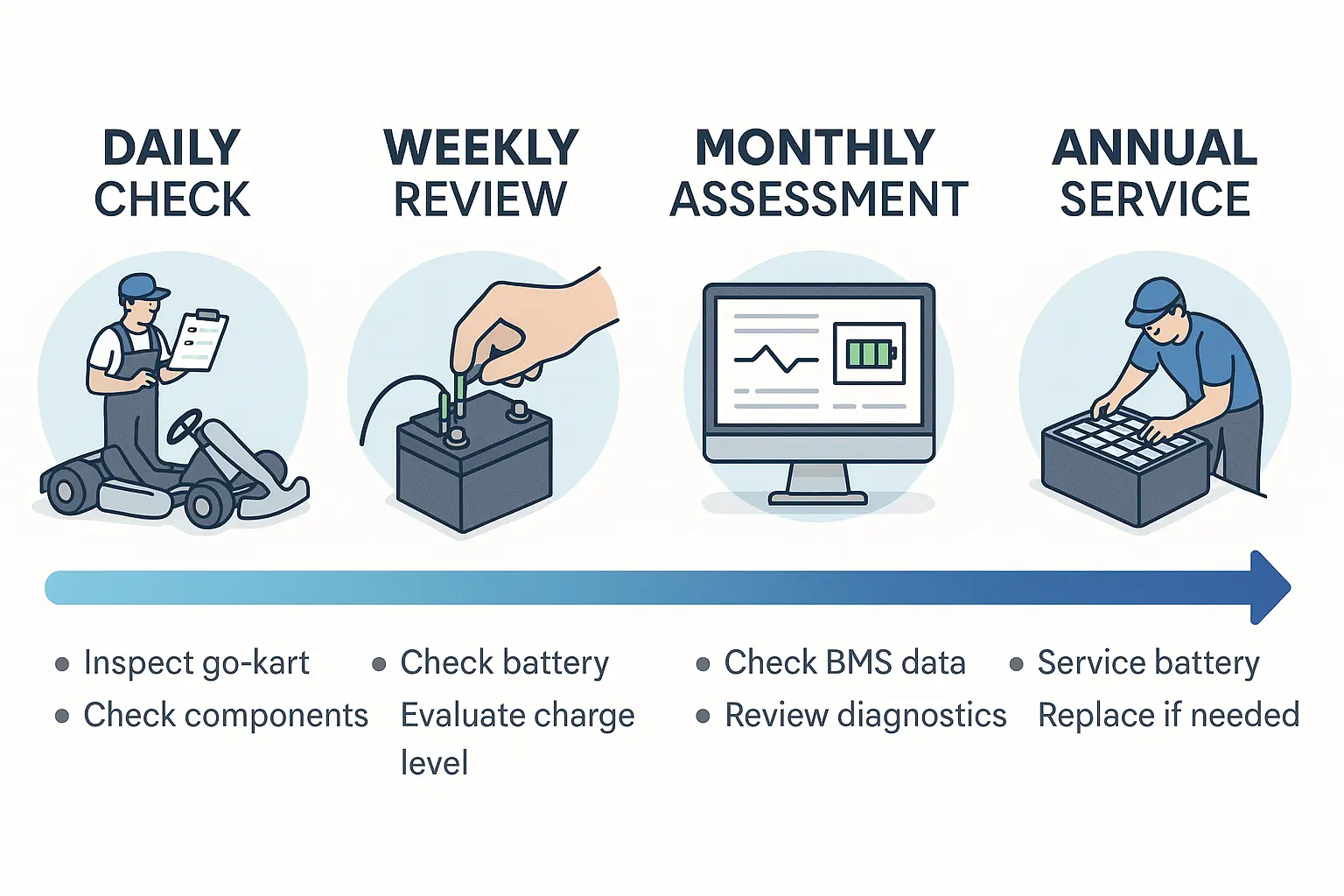

Regular maintenance is essential for keeping battery systems operating safely and efficiently. While electric systems require less frequent servicing than gas engines, they do need attention to maintain peak performance. A comprehensive inspection schedule should include visual checks of the battery casing for cracks, deformation, or other damage that could compromise protection.

Electrical connection inspections catch potential problems before they cause failures. Vibration and thermal cycling can gradually loosen connections over time, increasing electrical resistance and generating heat. Periodic checks ensure all terminals remain tight and corrosion-free, maintaining optimal conductivity throughout the system.

Warning signs that require immediate attention include unusual swelling of the battery pack, which could indicate internal cell damage or overcharging issues. Any burning smells, excessive heat during normal operation, or rapid loss of capacity between charges warrant professional inspection. Modern BMS systems often log error codes that trained technicians can retrieve, providing valuable diagnostic information about potential issues.

Professional servicing should occur at manufacturer-recommended intervals, typically annually for regularly used karts. These comprehensive inspections include detailed BMS diagnostics, capacity testing to assess battery health, thermal imaging to identify hot spots that might indicate developing problems, and verification that all safety systems function correctly.

At Minye Fun, we provide detailed maintenance guidelines with every go-kart and offer professional servicing to ensure your battery system continues performing at its best. Our technical support team is always available to answer questions about battery care and to help troubleshoot any concerns that arise.

Real-World Performance and Reliability

Battery Longevity in Racing Conditions

Racing is demanding, pushing equipment to its limits lap after lap. Quality battery systems are engineered to handle these stresses while maintaining performance over hundreds of charge cycles. Modern lithium-ion batteries designed for go-kart applications typically retain 80% or more of their original capacity even after 1,000 full charge-discharge cycles. For most recreational and commercial operations, this translates to several years of reliable service before any capacity degradation becomes noticeable.

The key to achieving this longevity lies in proper thermal management and avoiding deep discharges whenever possible. Batteries that are kept within their optimal operating temperature range and recharged before completely depleting will significantly outlast those subjected to thermal stress or frequent deep cycling. This is where quality BMS systems prove their worth, actively managing these parameters to maximize battery life.

Real-world testing has demonstrated that well-maintained electric go-kart batteries often outlast the lifecycle of gas engines used in comparable applications. While combustion engines accumulate wear with every running hour, battery degradation is primarily a function of charge cycles and time, meaning karts that see intermittent use experience very little aging between uses.

What Racers Are Saying

The proof of any technology lies in the experiences of those who use it daily. Karting facility operators consistently report that electric go-karts with quality battery systems require a fraction of the maintenance time compared to gas-powered fleets. This reliability translates directly to more available track time and improved profitability for commercial operations.

Competitive racers appreciate the consistency that battery-powered systems deliver. Knowing that your kart will perform identically from session to session eliminates one variable from race preparation, allowing drivers to focus purely on improving their skills and race craft. The instant throttle response and smooth power delivery create confidence, especially for newer racers who might struggle with the clutch engagement and power band characteristics of gas karts.

Indoor facility managers highlight the transformative effect of eliminating exhaust fumes and reducing noise levels. These improvements create a more pleasant environment that appeals to families and corporate groups, expanding the potential customer base beyond hardcore racing enthusiasts. The ability to operate in climate-controlled indoor spaces year-round provides business advantages that gas-powered operations simply cannot match.

Electric Versus Gas: The Reliability Comparison

When comparing reliability between electric and gas-powered go-karts, several factors come into play. Gas engines have more moving parts—pistons, valves, camshafts, and more—each representing a potential failure point. Electric motors, by contrast, contain only a few moving components, primarily the rotor and bearings. This mechanical simplicity translates to inherently higher reliability.

Fuel system issues plague gas-powered karts, from carburetor problems to fuel contamination and vapor lock in hot conditions. Electric systems eliminate these concerns entirely. There’s no fuel to go stale during storage, no jets to clog, and no fuel pumps to fail. The electrical simplicity of battery-to-controller-to-motor creates a robust system with fewer things that can go wrong.

Starting reliability strongly favors electric systems. Gas engines can be temperamental, especially in cold weather or after sitting unused. Battery-powered karts start instantly with the flip of a switch, regardless of ambient temperature or how long they’ve been stored. This consistent starting eliminates the frustration of flooding engines or draining batteries trying to get stubborn motors running.

Weather resistance is another area where electric systems excel. While gas engines can struggle with moisture affecting ignition systems or cold temperatures impacting fuel atomization, electric motors and sealed battery packs operate reliably across a much wider temperature range. This all-weather capability means fewer cancelled race days and more consistent operation.

Future Innovations in Battery Technology

Next-Generation Battery Chemistry

The battery technology powering today’s electric go-karts is impressive, but the next generation promises even more remarkable advances. Solid-state batteries, currently in advanced development, replace the liquid electrolyte in conventional lithium-ion cells with a solid material. This change potentially offers higher energy density, faster charging, improved safety, and longer lifespans.

Energy density improvements mean future battery packs could be significantly lighter while delivering the same power, or maintain current weights while extending range substantially. For go-kart applications, this could translate to longer racing sessions between charges or the ability to use smaller, more strategically placed battery packs that further optimize handling characteristics.

Charging speed is another frontier where breakthroughs are imminent. Research into advanced electrode materials and charging algorithms suggests that future systems might achieve 80% charges in 15 minutes or less without degrading battery life. For commercial karting operations, this rapid turnaround would be transformative, essentially eliminating charging time as a constraint on fleet utilization.

Sustainability and Environmental Commitments

The environmental benefits of electric go-karts extend beyond zero emissions during operation. Battery manufacturers are increasingly focused on sustainable sourcing of raw materials and developing recycling programs that recover valuable metals for reuse in new batteries. This circular economy approach addresses one of the primary environmental concerns associated with lithium-ion technology.

At Minye Fun, we’re committed to environmental responsibility throughout our product lifecycle. We partner with battery suppliers who prioritize ethical sourcing and maintain transparent supply chains. When batteries eventually reach the end of their useful life in our go-karts, we ensure they’re properly recycled through certified programs that safely recover materials and prevent environmental contamination.

Second-life applications for go-kart batteries represent another sustainability opportunity. Even when a battery has degraded to the point where it no longer meets the demanding performance requirements of racing, it typically still retains 70-80% of its original capacity. These retired kart batteries can be repurposed for less demanding applications like stationary energy storage, extending their useful life and maximizing the return on the environmental investment of manufacturing them.

Performance Enhancements on the Horizon

Beyond pure battery improvements, integrated system advances promise to enhance the overall electric go-kart experience. Wireless charging systems, already proven in other applications, could eliminate the need for physical charging connections. Imagine pulling into a designated pit spot and having your kart begin charging automatically through inductive power transfer—no cables to connect or disconnect.

Predictive maintenance powered by artificial intelligence will leverage the data continuously collected by BMS systems to forecast when components might need service before failures occur. Machine learning algorithms can identify patterns in battery performance that indicate developing issues, allowing proactive maintenance that prevents unexpected downtime.

Energy recovery systems, similar to those used in Formula E racing, could capture energy during braking and return it to the battery, extending range and adding another dimension to racing strategy. While current go-kart applications have weight and space constraints that make this challenging, miniaturization of regenerative braking systems may soon make this technology practical for recreational karts.

Enhanced connectivity features will allow racers and facility operators to monitor battery health and performance in real-time through smartphone apps. Detailed analytics about energy consumption, charging patterns, and battery condition will enable optimization of both racing performance and fleet management practices.

Conclusion: Technology Meets Safety on the Track

The battery technology powering modern electric go-karts represents a remarkable convergence of performance, safety, and sustainability. From the sophisticated chemistry within lithium-ion cells to the intelligent management systems that protect and optimize their operation, every aspect has been engineered to deliver an exceptional racing experience.

Safety isn’t an afterthought—it’s built into every layer of battery system design. Multiple redundant protection mechanisms, robust physical enclosures, and comprehensive monitoring systems work together to ensure that drivers can push their limits with confidence. The simplicity and reliability of electric powertrains mean less time worrying about mechanical issues and more time enjoying the pure thrill of racing.

The performance advantages speak for themselves. Instant torque, consistent power delivery, optimized weight distribution, and whisper-quiet operation create a racing experience that’s simply not possible with traditional gas-powered karts. As battery technology continues advancing, these benefits will only become more pronounced.

At Minye Fun, we’re passionate about delivering cutting-edge electric go-karts that showcase what’s possible when innovative battery technology meets thoughtful design. Our commitment to quality, safety, and performance is reflected in every kart we produce. We don’t just sell go