Production Process for Sealed Air Inflatable Products

Sealed air inflatable products have become popular for various applications, from promotional items and advertising displays to cushioning and packaging materials. The production of these products involves several essential steps to ensure quality, durability, and customer satisfaction. While variations may exist based on specific product types, equipment, and process management, the following comprehensive process provides insights into the manufacturing of sealed air inflatable products.

1. Design

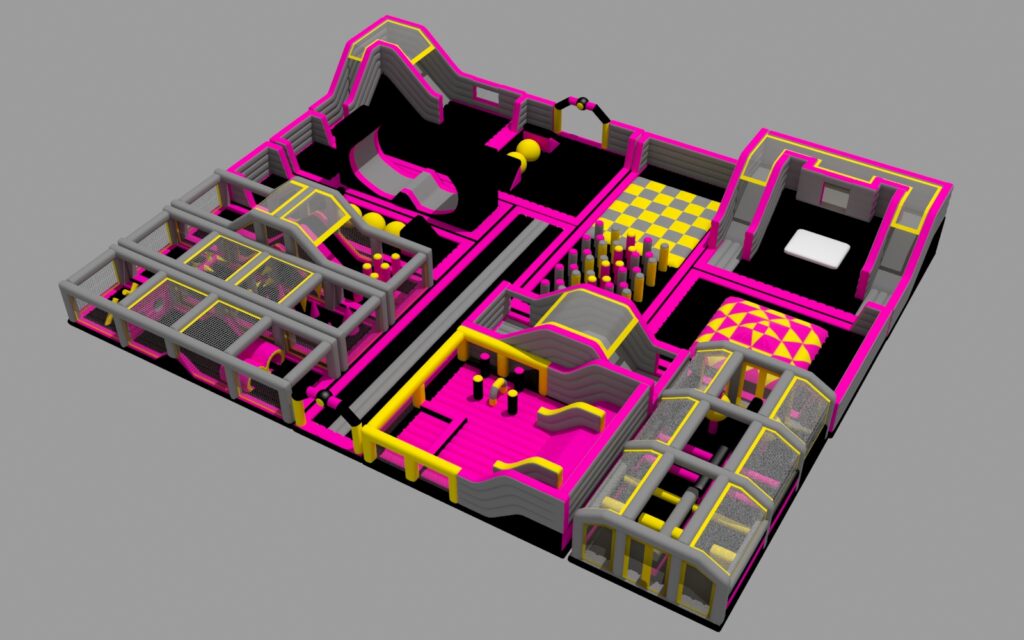

The production process for sealed air inflatable products begins with the design phase. This step is crucial in determining the product’s visual appeal and functionality. Designers work closely with customers to understand their requirements, which include dimensions, shape, color, and any branding elements such as logos. The design phase ensures that the inflatable product aligns with the customer’s vision and marketing goals.

2. Pattern-Making

After finalizing the design, the next step is pattern-making. Advanced Computer-Aided Design (CAD) and pattern-making software are employed to create precise cutting files. These cutting files serve as the foundation for the subsequent cutting and production processes. They are meticulously crafted to provide accurate references, ensuring that the inflatable products are consistent in size and shape.

3. Cutting

Cutting is a critical step in producing sealed air inflatable products. Automated cutting equipment is used, guided by the cutting files created in the previous step. This automation ensures precision in cutting and optimizes material utilization, reducing waste. The selected materials, typically high-quality PVC or similar materials, are cut into the required shapes and sizes. Accurate cutting is essential to achieving uniform product quality.

4. Printing

Printing adds the visual elements to the inflatable products. High-quality printing equipment and eco-friendly ink are utilized to ensure consistent and vibrant patterns, as well as accurate reproduction of logos and designs. The quality of the printing process directly affects the visual appeal and branding of the inflatable product. It’s vital to maintain a high standard to meet customer expectations.

5. Hot Welding

Hot welding is a crucial step in creating sealed air inflatable products. Skilled welding technicians are continuously trained to improve both the quality and efficiency of the welding process. The welding process is optimized to ensure the precise joining of cut materials. Specialized machines and techniques are used to create strong and aesthetically pleasing weld lines. Proper welding is essential not only for product aesthetics but also for maintaining a stable and secure product structure.

The welding process typically involves heating the edges of the cut material and then pressing them together, creating a hermetic seal. The quality of the welding process directly impacts the product’s ability to maintain inflation over time.

6. Inflation Testing

Inflation testing is a crucial quality control step in the production of sealed air inflatable products. In this step, the sealed inflatable products are inflated using pumps. The goal is to ensure that the products can maintain inflation and sustain a specified period of time, thus verifying their airtightness. Only products that pass the airtightness test proceed to the next steps of the production process.

This quality control step is essential to guarantee the durability, safety, and functionality of the inflatable products. Products that fail this test are identified and rectified to meet the required quality standards.

7. Packaging

The final step in the production process is packaging. Developing an effective packaging solution is critical to protect the finished inflatable products during transportation and storage. The packaging design is tailored to the specific product type and the method of transportation, ensuring that the products arrive at their destination in pristine condition.

Reliable packaging materials and techniques are used to safeguard the integrity of the inflatable products. This includes protective layers, cushioning, and proper sealing to prevent any damage during transit. The packaging process is essential to ensure that customers receive products that meet their quality expectations.