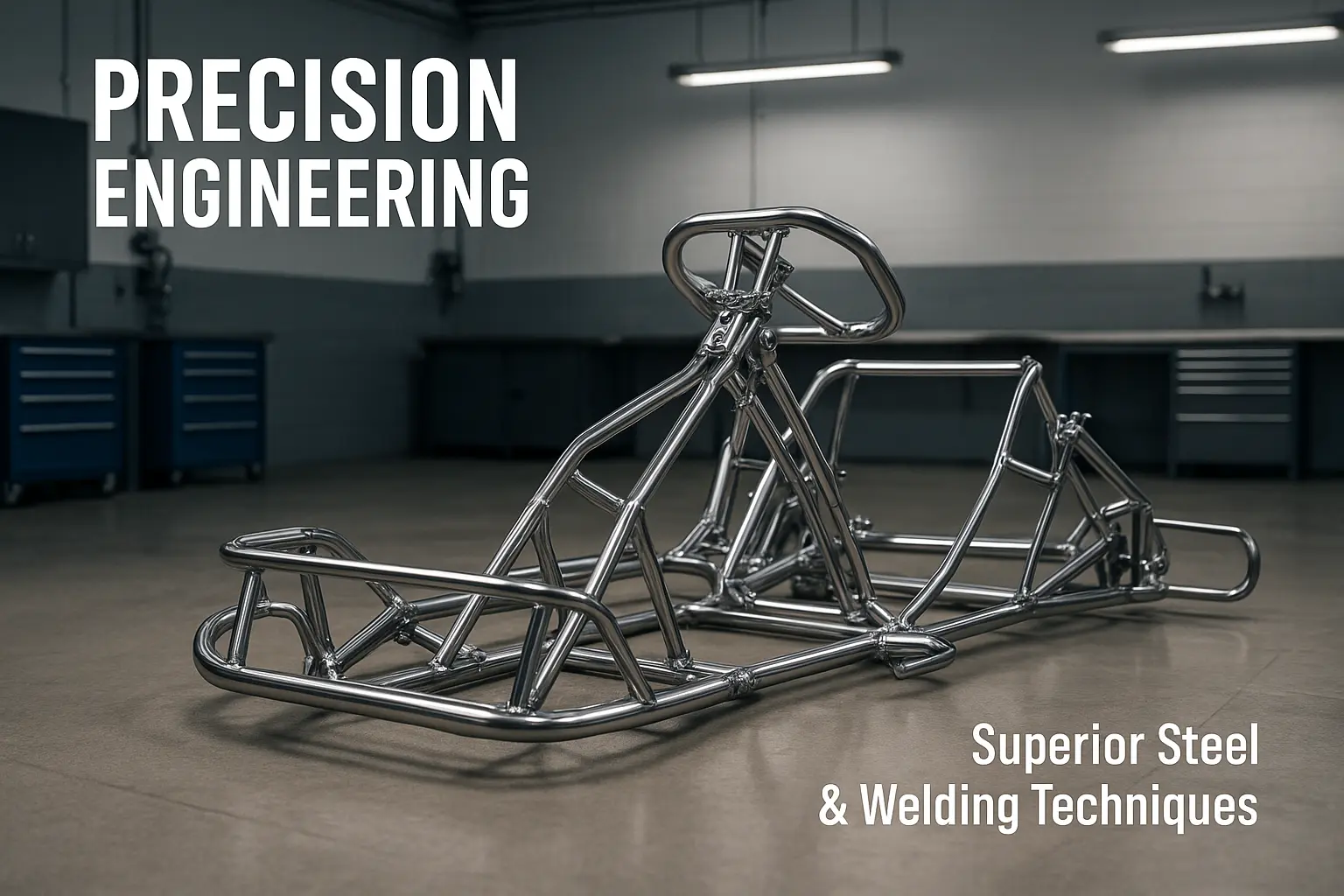

The difference between a weekend hobby kart and a championship-winning machine often comes down to one crucial element: the chassis. While engines grab attention and tires touch the track, it’s the steel frame beneath that determines whether your go-kart will handle like a dream or become a safety hazard. Understanding the relationship between high-grade steel selection and precision welding techniques isn’t just technical knowledge—it’s the foundation of go-kart performance, safety, and longevity.

Understanding Go-Kart Chassis Materials: The Steel That Makes Champions

When building or purchasing a go-kart chassis, the steel selection process represents your most critical decision. Two primary materials dominate the go-kart manufacturing landscape, each with distinct advantages that serve different purposes and budgets.

Chrome Moly Steel: The Professional’s Choice

Chrome moly steel, specifically 4130 alloy, contains chromium and molybdenum that create exceptional strength-to-weight ratios. Professional racing teams consistently choose this material because it delivers 25-30% weight reduction compared to mild steel while maintaining superior structural integrity. The chromium content provides corrosion resistance, while molybdenum enhances hardenability and high-temperature strength—crucial factors when chassis experience extreme racing conditions.

Racing kart manufacturers favor chrome moly because it allows thinner wall tubing without compromising strength. A typical 4130 chassis uses 0.049″ to 0.065″ wall thickness, compared to the 0.083″ to 0.120″ required for equivalent mild steel construction. This weight savings translates directly to improved acceleration, better handling response, and reduced tire wear during extended racing sessions.

Mild Steel: The Builder’s Foundation

Mild steel (1018 or A36) remains the preferred choice for recreational go-karts and DIY builders. Its lower carbon content makes it significantly easier to weld, bend, and repair, making it ideal for hobbyists learning chassis construction. The material costs approximately 40-50% less than chrome moly, making it accessible for budget-conscious builders.

The forgiving nature of mild steel welding means fewer heat-affected zone concerns and simpler joint preparation. Weekend mechanics can achieve professional-quality results with basic MIG welding equipment, whereas chrome moly typically requires TIG welding expertise and precise heat control.

Steel Quality Factors That Determine Performance

Beyond material type, steel quality variations significantly impact chassis performance and construction difficulty. Cold-drawn tubing offers superior dimensional accuracy and surface finish compared to hot-rolled alternatives. The cold-drawing process creates consistent wall thickness and improved mechanical properties, resulting in more predictable welding behavior and better fatigue resistance.

Seamless tubing eliminates the potential weak point created by seam welding in standard tubing. While more expensive, seamless construction provides consistent strength properties throughout the tube circumference—a critical factor for high-stress applications like racing chassis main rails and engine mounts.

Wall thickness selection requires balancing strength, weight, and cost considerations. Racing regulations often specify minimum wall thickness requirements, but builders must consider local stress concentrations around suspension mounting points, engine mounts, and driver protection areas.

Critical Welding Techniques for Superior Chassis Construction

The welding process selection fundamentally determines chassis quality, regardless of steel type chosen. Each welding method offers specific advantages that match different skill levels, production requirements, and quality standards.

TIG Welding: Precision for Performance

TIG (Tungsten Inert Gas) welding represents the gold standard for go-kart chassis construction, particularly when working with chrome moly steel. The process provides superior control over heat input and produces clean, precise welds essential for thin-wall tubing. Professional chassis builders rely on TIG welding because it minimizes heat-affected zones that can weaken chrome moly steel.

The precise control offered by TIG welding allows welders to manage penetration depth, bead appearance, and heat input with exceptional accuracy. This control becomes critical when welding different wall thicknesses together or creating complex joint geometries common in modern chassis designs. The resulting welds exhibit superior fatigue resistance and aesthetic appeal demanded by professional racing applications.

MIG Welding: Accessibility and Efficiency

MIG (Metal Inert Gas) welding offers an excellent balance between quality and accessibility for go-kart chassis construction. The process provides user-friendly operation that allows DIY builders to achieve professional-quality results with proper technique and equipment setup. Modern MIG welders with pulse capabilities can produce excellent results on mild steel chassis construction.

The higher deposition rates of MIG welding make it preferred for production environments where efficiency matters. However, successful MIG welding of go-kart chassis requires careful attention to wire selection, shielding gas composition, and travel speed to avoid common defects like porosity or inadequate penetration.

Weld Quality and Heat Management: The Foundation of Safety

Heat-affected zone management represents perhaps the most critical aspect of go-kart chassis welding. Excessive heat input can significantly reduce steel strength in areas adjacent to welds, creating potential failure points under racing loads. Chrome moly steel particularly requires careful heat control to prevent embrittlement and maintain desired mechanical properties.

Common failure points include inadequately penetrated joints, excessive heat input causing material degradation, and poor joint preparation leading to incomplete fusion. Professional builders implement specific techniques like back-purging, precise fit-up procedures, and controlled cooling rates to ensure consistent weld quality throughout the chassis.

Post-weld heat treatment considerations become important for high-stress applications. While most go-kart chassis don’t require formal heat treatment, understanding the effects of welding heat on steel properties helps builders make informed decisions about joint design and welding procedures.

Manufacturing Best Practices: Building for Performance and Safety

Frame design philosophy significantly impacts both performance and manufacturing difficulty. Tubular construction offers optimal strength-to-weight ratios while providing design flexibility for complex geometries. Joint design must consider stress distribution patterns and avoid sharp corners that create stress concentrations.

Fixture and jig usage ensures dimensional accuracy and repeatability in chassis construction. Professional manufacturers invest heavily in welding fixtures that maintain precise tube positioning during welding operations. These fixtures prevent distortion, ensure proper alignment, and improve overall chassis geometry consistency.

Quality control measures extend beyond visual weld inspection. Dimensional verification, stress testing, and systematic inspection protocols help identify potential issues before they become safety hazards. Many manufacturers implement dye penetrant testing on critical welds to detect surface cracks invisible to visual inspection.

Performance Impact: How Steel and Welding Affect Your Racing Experience

Chassis rigidity directly influences handling characteristics and driver feedback. Proper steel selection and welding techniques create optimal torsional stiffness that improves cornering precision and reduces unwanted chassis flex. A well-constructed chrome moly chassis provides immediate steering response and predictable handling characteristics that competitive drivers demand.

Weight distribution optimization becomes possible only with precise manufacturing techniques. Consistent welding quality ensures that designed weight distribution remains accurate throughout the chassis construction process. Variations in weld quality can shift weight distribution and affect handling balance in subtle but measurable ways.

The maintenance and repair advantages of proper construction become apparent over time. High-quality welds resist fatigue cracking, while properly selected materials maintain structural integrity under repeated stress cycles. This durability translates to lower long-term ownership costs and improved safety margins.

Safety Implications: Why Quality Construction Saves Lives

Chassis failure consequences in go-kart racing can be severe, making quality construction a safety imperative rather than a performance luxury. Regulatory compliance requirements often specify minimum construction standards precisely because chassis integrity directly impacts driver safety. Understanding these requirements helps builders prioritize critical areas that require extra attention.

Crashworthiness considerations influence both material selection and joint design. Modern chassis design incorporates deformation zones that absorb impact energy while maintaining driver cell integrity. These design features only function properly when executed with appropriate materials and welding techniques.

Regular inspection protocols help identify potential problems before they become dangerous. Crack detection, joint integrity verification, and overall structural assessment should be routine maintenance items for any serious go-kart operation.

Cost-Benefit Analysis: Investment Decisions That Matter

Initial investment considerations must balance immediate costs against long-term value and safety requirements. While chrome moly construction costs 50-70% more than mild steel initially, the performance advantages, weight savings, and durability often justify the investment for serious racers.

Professional construction versus DIY approaches each offer distinct advantages. Professional builders bring expertise, proper equipment, and quality assurance protocols that ensure optimal results. However, DIY construction provides learning opportunities, cost savings, and the satisfaction of building your own equipment.

Market comparison reveals significant variation in chassis quality and pricing. Understanding the relationship between materials, construction techniques, and pricing helps buyers make informed decisions that match their specific needs and budgets.

For those seeking professional-quality chassis construction and expert guidance, companies like Minye Jewelry offer specialized manufacturing services that combine traditional craftsmanship with modern techniques to deliver exceptional results.

Conclusion: Building the Foundation for Success

The importance of high-grade steel and precision welding techniques in go-kart chassis manufacturing cannot be overstated. These fundamental decisions determine safety, performance, durability, and overall satisfaction with your go-kart experience. Whether choosing chrome moly for professional racing applications or mild steel for recreational use, understanding the relationship between materials, welding techniques, and performance outcomes enables informed decisions that serve your specific needs.

Success in go-kart chassis construction requires matching material selection to intended use, implementing appropriate welding techniques for chosen materials, and maintaining consistent quality standards throughout the construction process. The investment in proper materials and techniques pays dividends in performance, safety, and long-term satisfaction with your go-kart experience.

Remember that chassis construction represents the foundation upon which all other go-kart systems depend. Engine performance, suspension effectiveness, and driver safety all rely on the structural integrity and precision of the chassis beneath them. Making informed decisions about steel quality and welding techniques ensures that your go-kart will provide years of safe, competitive, and enjoyable racing experience.