- One-Stop Supplier for Entertainment Games

- 86-137 1133 5861

- sales@minyefun.com

As autumn leaves begin to fall and temperatures drop, it’s time to think about properly storing your inflatable products for the off-season. Whether you operate a customized inflatable factory or own commercial inflatables for events and entertainment, proper storage is crucial for maintaining product quality and extending lifespan.

At our inflatable manufacturing facility, we’ve helped countless customers preserve their investments through proper seasonal maintenance. This comprehensive guide will walk you through the professional steps needed to ensure your inflatables remain in pristine condition throughout autumn and winter, ready to bounce back into action when warmer weather returns.

Inflatable products face unique challenges during colder months. Temperature fluctuations, moisture buildup, and extended periods of inactivity can lead to:

Following our factory-tested storage protocol can prevent these issues and save you significant replacement costs.

Never store a dirty inflatable. Contaminants left on the surface can cause permanent staining and material breakdown over time.

Begin by deflating your inflatable completely. Using a soft cloth or sponge dampened with neutral soapy water or mild detergent, gently wipe down the entire surface. Pay special attention to high-traffic areas where dirt, grass stains, and body oils tend to accumulate.

Work in sections, rinsing your cloth frequently to avoid spreading dirt. For best results, clean on a mild, dry day when you can work outdoors or in a spacious area.

For persistent stains that won’t budge with regular cleaning, apply a dedicated PVC cleaner specifically formulated for inflatable materials. Important: Avoid harsh chemicals including:

These substances can compromise the material’s integrity, causing discoloration, brittleness, or seal failures. Always test any cleaning product on a small, inconspicuous area first.

This often-overlooked step is critical for long-term storage success. Spray a diluted PVC-friendly disinfectant across the entire surface, concentrating on seams, folds, and any areas that trap moisture. This prevents mold, mildew, and bacterial growth during the dormant months.

Look for disinfectants labeled as safe for vinyl or PVC materials, and follow the manufacturer’s dilution instructions carefully.

This cannot be overstated: Moisture is the enemy of stored inflatables. Even trace amounts can trigger mold growth, create musty odors, and damage bonded seams.

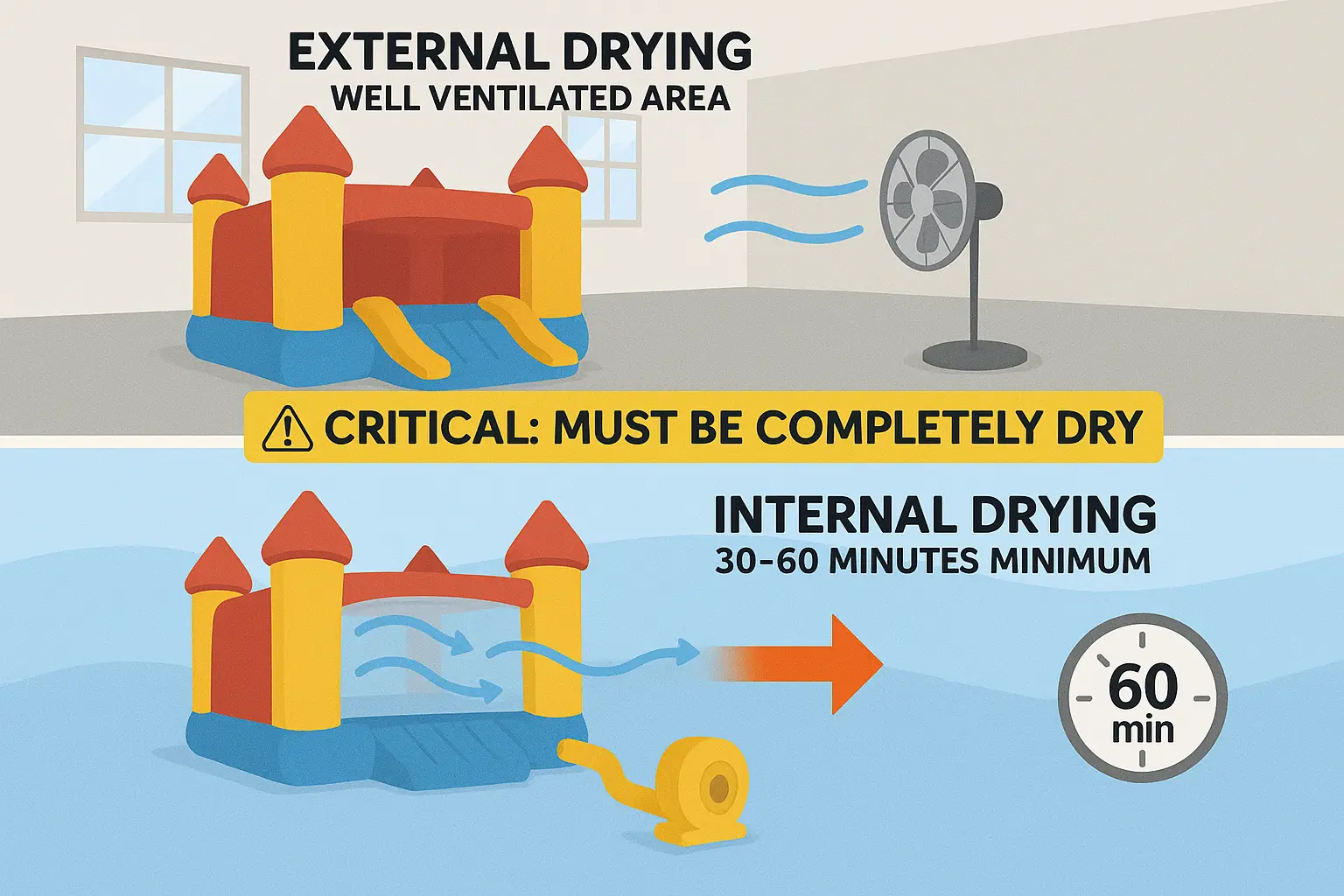

After cleaning and disinfecting, use clean, absorbent towels to pat down all surfaces. Then move the inflatable to a well-ventilated, shaded indoor area for air drying. Direct sunlight may seem like a quick drying solution, but UV rays can degrade PVC materials over time.

Open windows or use fans to promote air circulation. Depending on size and humidity levels, external drying may take several hours.

Here’s where many storage attempts fail. The interior chambers of your inflatable also collect moisture during use and cleaning. To dry the inside properly:

Consider this your insurance policy against mold. The time invested here pays dividends in product longevity.

Before moving to the next step, verify complete dryness by:

If in doubt, give it another hour of drying time.

Once your inflatable is bone-dry, it’s time to add a protective layer against the rigors of storage.

Specialized PVC/vinyl protectants create a barrier that:

Apply an even, light coating across all surfaces following the product instructions. Don’t oversaturate—a thin, uniform layer is more effective than heavy application. Allow the protectant to dry completely before proceeding to packing (typically 20-30 minutes).

This step is particularly important for inflatables stored in areas with temperature fluctuations or less-than-ideal humidity control.

How you pack your inflatable directly impacts how it emerges from storage.

Avoid tight, sharp folds. These create stress points where material can crack or weaken over time. Instead:

Think of folding a sleeping bag rather than a suitcase. The goal is compact storage without material stress.

If you’ve retained the original storage bag, use it—these are designed with proper ventilation and sizing. If not available, secure the rolled inflatable with soft straps (avoid using rope, which can create pressure points). Position straps at regular intervals without over-tightening.

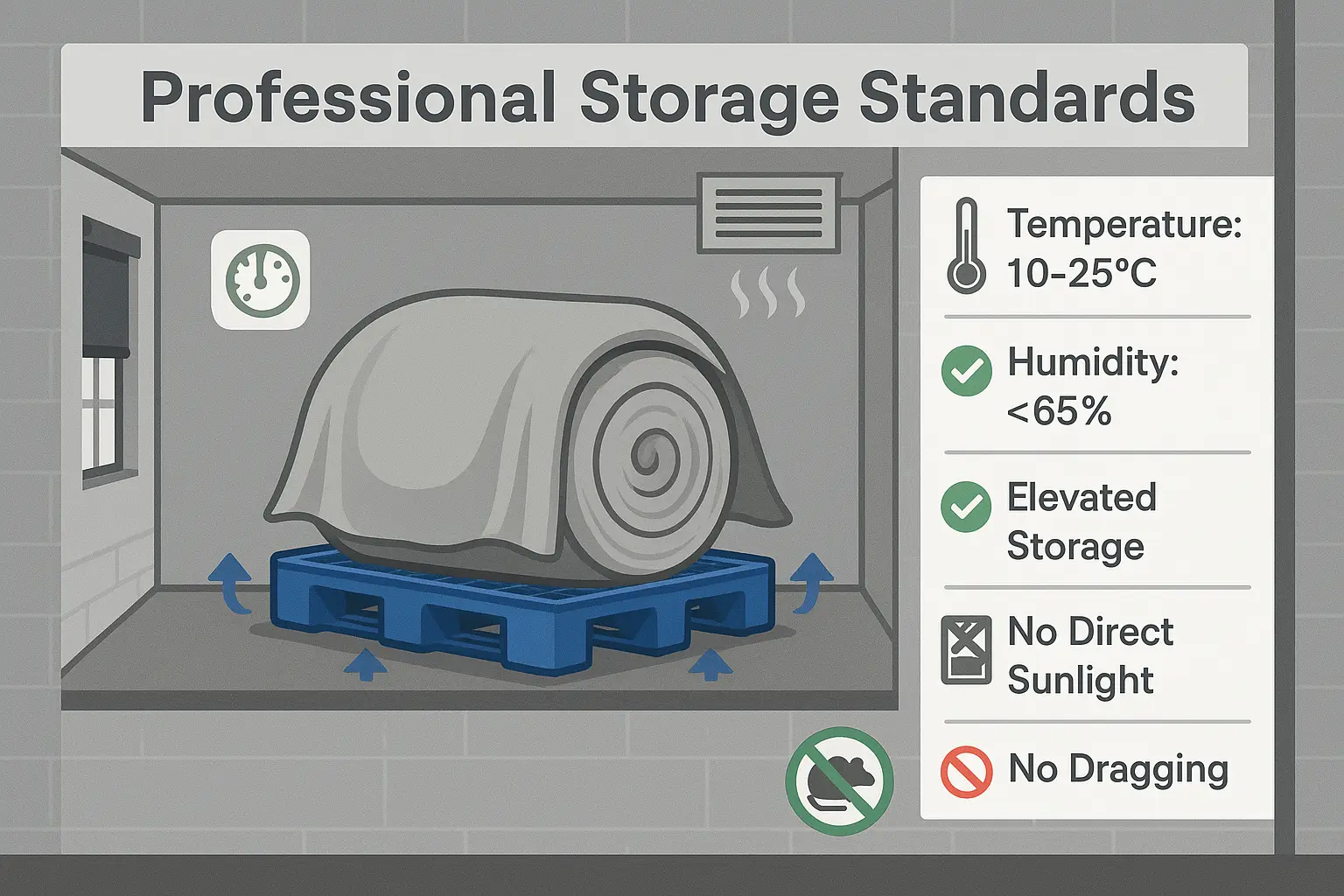

Storage conditions make or break your preservation efforts. Here’s how professionals at our customized inflatable factory prepare products for long-term storage.

Use a breathable PVC dust-proof tarpaulin to cover your packed inflatable. Breathable materials allow any minimal moisture to escape, preventing condensation—a common problem with standard plastic sheeting.

Pro tip: If you don’t have a specialized tarp, repurpose the original packaging bag by cutting it open and wrapping it around the rolled inflatable. This provides familiar material contact and some protection.

Never store inflatables directly on the floor. Ground-level storage exposes products to:

Place covered inflatables on plastic pallets (preferable to wood, which can harbor moisture and pests). Ensure the pallet surface is smooth or add a PVC sheet layer to prevent any surface abrasion.

This elevation creates airflow underneath, regulates temperature, and provides a clean barrier from ground-level hazards.

Your storage environment should meet these specifications:

Temperature: Maintain between 10°C and 25°C (50°F to 77°F)

Humidity: Keep below 65% relative humidity

Light: Protect from direct sunlight

Ventilation: Ensure good air circulation

Conduct monthly inspections of your storage area:

Rodents find inflatable materials attractive for nesting. A single breach can cause extensive damage requiring professional repair or replacement.

Never drag an inflatable product—packed or unpacked—across any surface. Always lift and carry, even short distances. Dragging causes:

For larger inflatables, use adequate personnel or material handling equipment to avoid dragging temptation.

When warmer weather returns and it’s time to bring your inflatable out of hibernation:

Following this professional storage protocol may seem time-intensive initially, but consider the mathematics:

The storage investment returns multiples through:

At our customized inflatable factory, we engineer products for durability, but materials science has limits. PVC and vinyl materials respond to environmental conditions:

By controlling these variables during storage, you maintain the material properties we build into every product during manufacturing.

Protecting your inflatable investment through autumn and winter requires attention to detail but rewards you with years of reliable performance. Remember the essential steps:

While proper storage extends inflatable life significantly, starting with quality manufacturing makes the biggest difference. Products from our customized inflatable factory are engineered with:

Combined with the storage practices outlined in this guide, you’re ensuring maximum return on your inflatable investment.

Have questions about storing specific inflatable types or need custom solutions? Contact our team at the customized inflatable factory for personalized guidance. We’re committed to helping you maintain the quality and performance of your inflatable products season after season.

Thank you for choosing quality inflatables and for taking the time to care for them properly. Here’s to many more seasons of fun, function, and profit from your well-maintained inflatable investments!