The inflatable industry has experienced remarkable growth over the past decade, expanding from simple pool toys to sophisticated commercial applications. Whether you’re a business owner looking to invest in promotional inflatables or an event organizer seeking entertainment solutions, understanding industry terminology is crucial for making informed decisions and communicating effectively with manufacturers.

This comprehensive guide breaks down the essential terms you’ll encounter when working with inflatable products, helping you navigate the industry with confidence.

Manufacturing & Production Terms

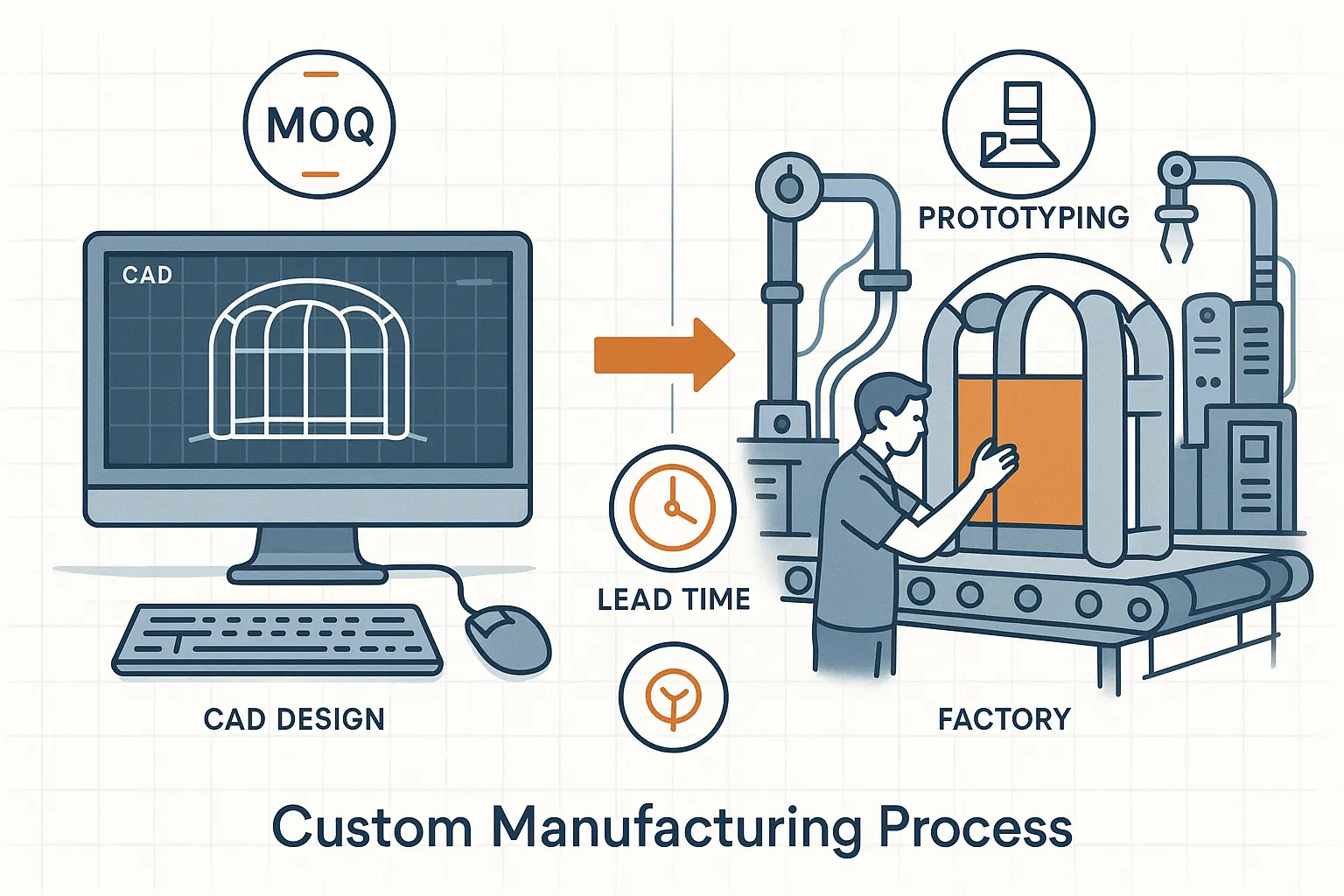

Custom Manufacturing refers to the process of creating inflatables tailored to specific requirements rather than purchasing standard, off-the-shelf products. This approach allows businesses to incorporate unique designs, specific dimensions, and branded elements that align with their marketing goals or functional needs.

Prototyping is the crucial first step in custom inflatable development. During this phase, manufacturers create sample products to test design concepts, validate functionality, and ensure the final product meets specifications. A well-executed prototype phase can save significant time and costs in mass production.

Lead Time represents the duration from order confirmation to product delivery. For custom inflatables, lead times typically range from 2-6 weeks depending on complexity, quantity, and current production schedules. Understanding lead times helps businesses plan their marketing campaigns and events effectively.

MOQ (Minimum Order Quantity) indicates the smallest number of units a manufacturer will produce for a single order. MOQs exist because setup costs for custom inflatables are substantial, and manufacturers need to ensure orders are economically viable. Most reputable manufacturers offer reasonable MOQs that balance affordability with quality.

Materials & Construction Terminology

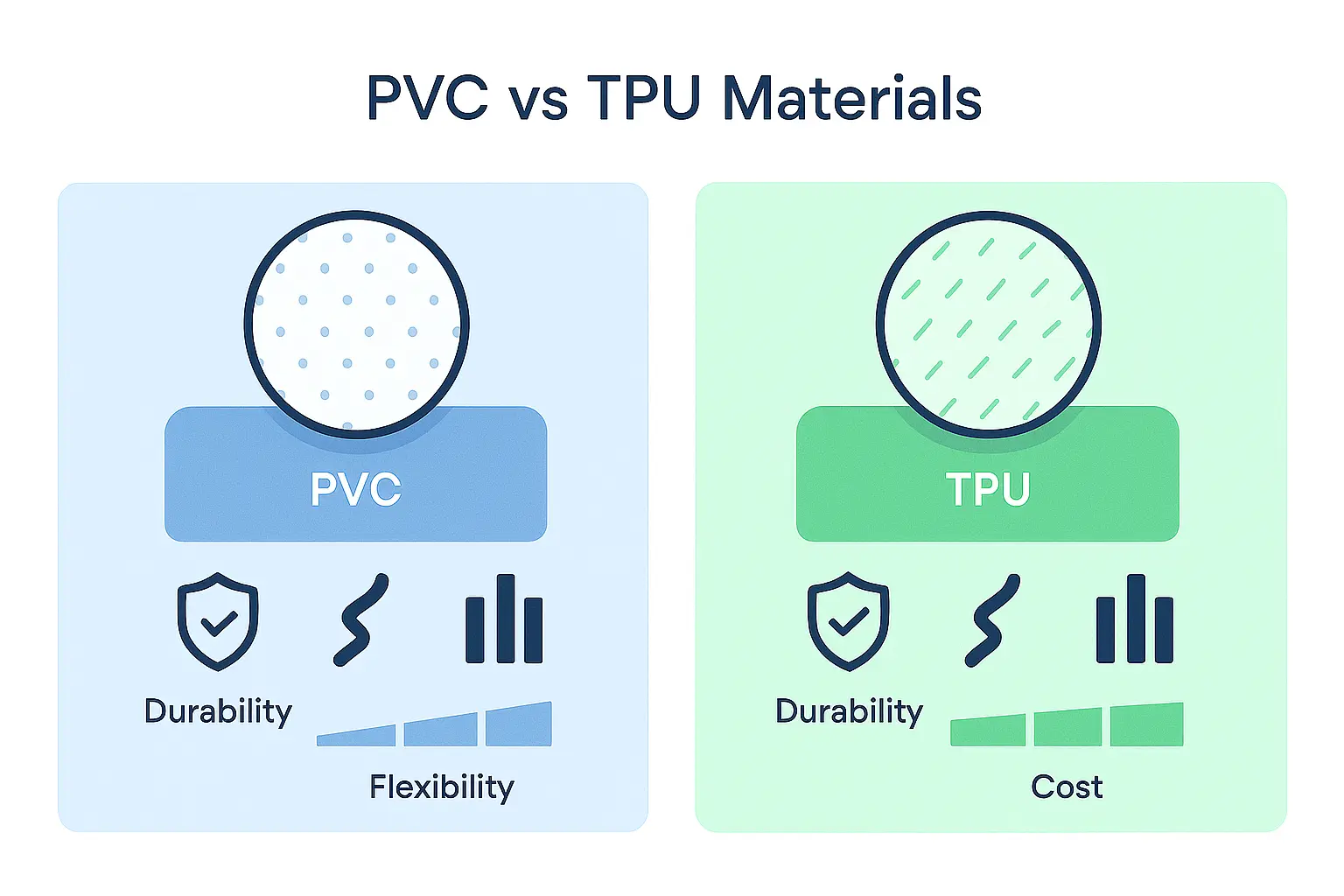

PVC vs. TPU represents two primary material choices in inflatable manufacturing. PVC (Polyvinyl Chloride) offers excellent durability and cost-effectiveness, making it ideal for commercial applications. TPU (Thermoplastic Polyurethane) provides superior flexibility and environmental resistance, though at a higher cost point.

Welding Techniques determine how inflatable seams are joined. Heat sealing creates strong, permanent bonds suitable for most applications. RF welding offers precision for complex shapes, while adhesive bonding provides flexibility for specialized designs. The choice depends on the product’s intended use and durability requirements.

Reinforcement involves adding extra material layers at stress points to prevent premature failure. Common reinforcement areas include seams, anchor points, and high-wear zones. Proper reinforcement significantly extends product lifespan, especially for commercial-grade inflatables.

Coating Types affect both appearance and performance. Protective coatings enhance UV resistance, reduce fading, and improve cleaning ease. Anti-slip coatings increase safety on walking surfaces, while specialized coatings can provide fire retardancy or antibacterial properties.

Design & Specifications

CAD Design utilizes computer-aided design software to create precise inflatable blueprints. Professional CAD work ensures accurate dimensions, proper stress distribution, and efficient material usage. This technology enables manufacturers to visualize complex designs before production begins.

Artwork Requirements specify the technical standards for graphics and branding elements. Print-ready files should be high-resolution, properly formatted, and include appropriate bleed areas. Understanding these requirements prevents delays and ensures optimal print quality.

Dimensional Tolerance acknowledges that inflatable products cannot achieve absolute precision in size. Typical tolerances range from 2-5% of stated dimensions due to material properties and inflation variables. Reputable manufacturers clearly communicate these tolerances upfront.

Weight Capacity indicates the maximum load an inflatable can safely support. This specification is critical for bounce houses, slides, and other entertainment products. Manufacturers determine capacity through rigorous testing and apply safety margins to ensure user protection.

Quality & Safety Standards

CE Certification demonstrates compliance with European safety standards, though many global manufacturers pursue this certification to demonstrate quality commitment. CE marking indicates that products meet stringent safety, health, and environmental requirements.

Material Testing encompasses various assessments including tensile strength, UV resistance, and flame retardancy. These tests ensure materials perform reliably under normal use conditions and extreme environmental factors. Comprehensive testing protocols distinguish professional manufacturers from budget alternatives.

Quality Control involves systematic inspection processes throughout production. This includes material inspection, seam testing, pressure testing, and final product verification. Robust quality control systems minimize defects and ensure consistent product performance.

Safety Features include elements like emergency exits, secure anchoring systems, and clear user guidelines. These features are particularly important for entertainment inflatables where user safety is paramount. Professional manufacturers integrate safety considerations into every design aspect.

Commercial & Pricing Terms

FOB vs. CIF represents different shipping arrangements that affect total costs. FOB (Free on Board) means buyers handle shipping and customs from the departure port, while CIF (Cost, Insurance, and Freight) includes delivery to the destination port. Understanding these terms helps accurately compare quotes from different suppliers.

Bulk Pricing offers volume discounts for larger orders. Manufacturers typically establish tier structures where unit costs decrease as quantities increase. These pricing models reflect reduced per-unit setup costs and improved production efficiency.

Customization Fees cover additional costs for personalized elements like unique shapes, special colors, or complex graphics. While customization adds value, understanding associated costs helps businesses budget effectively for their specific requirements.

Warranty Terms define coverage periods and claim procedures. Reputable manufacturers offer comprehensive warranties covering material defects and workmanship issues. Clear warranty terms demonstrate manufacturer confidence in product quality.

Applications & Market Segments

Commercial Grade products are designed for intensive use in rental businesses, theme parks, and public events. These inflatables feature reinforced construction, premium materials, and enhanced safety features to withstand frequent use and various weather conditions.

Promotional Items serve marketing and branding purposes at trade shows, grand openings, and corporate events. These products prioritize visual impact and brand visibility while maintaining sufficient durability for temporary use.

Entertainment Products include bounce houses, slides, and interactive games designed for fun and engagement. Safety features, user capacity, and durability are primary considerations for these applications.

Industrial Uses encompass temporary structures, emergency shelters, and specialized applications like inflatable dams or containment systems. These products require specific engineering and often must meet unique regulatory requirements.

Making Informed Decisions

Understanding these industry terms empowers buyers to make informed decisions and communicate effectively with manufacturers. Whether you’re planning a marketing campaign, organizing an event, or exploring commercial opportunities, proper terminology knowledge ensures productive discussions and successful outcomes.

For businesses seeking reliable inflatable solutions, partnering with experienced manufacturers like Minye Fun can provide valuable guidance throughout the selection and customization process. Professional manufacturers not only deliver quality products but also educate customers about industry standards and best practices.

The inflatable industry continues evolving with new materials, technologies, and applications emerging regularly. Staying informed about key terminology and industry developments helps businesses leverage these innovations effectively while avoiding common pitfalls.

By understanding these essential terms, you’re better equipped to navigate the inflatable industry successfully, whether you’re a first-time buyer or an experienced professional seeking to expand your knowledge. Remember that reputable manufacturers are always willing to explain terminology and help customers make the best choices for their specific needs.