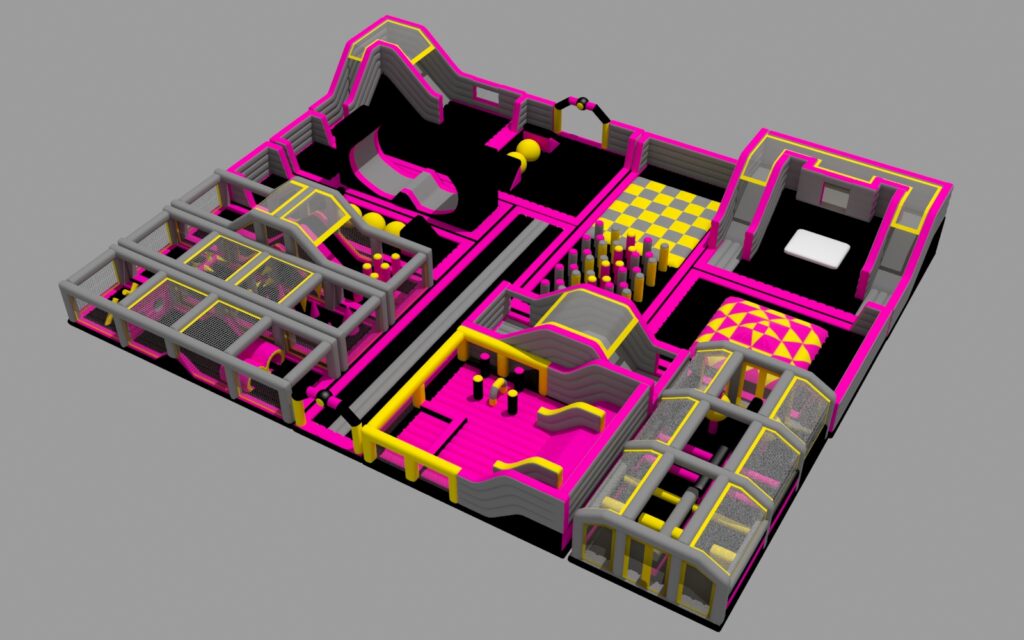

When it comes to inflatable entertainment equipment, there’s no room for compromise on safety. Every bounce, slide, and play session depends on the quality and reliability of the product. At Minye Fun, we understand that parents, event organizers, and business owners trust us with their most precious assets – their children’s safety and their business reputation.

Quality control isn’t just a checkbox in our manufacturing process; it’s the foundation of everything we do. From the moment raw materials enter our facility to the final inspection before shipping, every inflatable undergoes rigorous testing and validation to ensure it meets the highest safety and durability standards.

Industry Standards We Follow

The inflatable industry operates under strict safety regulations, and we exceed these requirements at every level. Our manufacturing processes comply with ASTM F2374 standards, which govern the design, manufacture, installation, operation, maintenance, and inspection of inflatable amusement devices. This comprehensive standard covers everything from structural integrity to emergency procedures.

We also maintain ISO 20187 certification, ensuring our products meet international safety requirements for inflatable play equipment. Additionally, our European market products comply with EN14960 standards, demonstrating our commitment to global safety excellence.

Third-party auditing plays a crucial role in our quality assurance program. Independent inspectors regularly evaluate our facilities, processes, and products to verify compliance with industry standards. This external validation provides an additional layer of confidence for our customers and ensures we maintain the highest quality benchmarks.

Material Selection and Testing

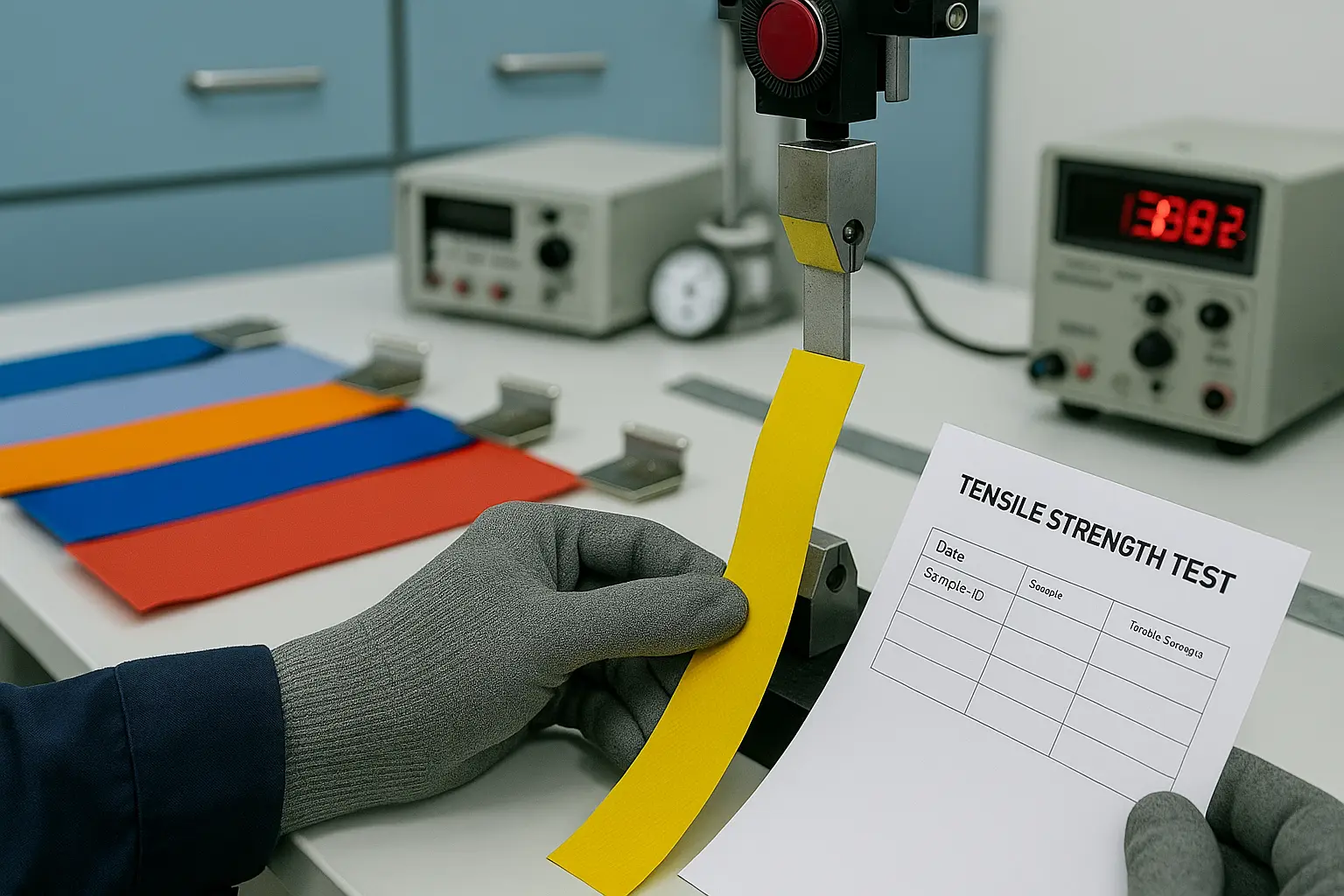

Quality inflatables start with premium materials. We exclusively use commercial-grade PVC fabric that meets strict durability and safety criteria. Our material selection process evaluates tensile strength, puncture resistance, and UV stability to ensure long-lasting performance in various weather conditions.

Every batch of raw materials undergoes comprehensive testing before entering production. We conduct tensile strength tests to verify the fabric can withstand operational stresses, puncture resistance evaluations to ensure durability during active play, and chemical safety verification to confirm all materials are non-toxic and safe for children.

Environmental resistance testing is particularly important for outdoor inflatables. Our materials undergo accelerated weathering tests that simulate years of sun exposure, temperature fluctuations, and moisture exposure. This ensures your inflatable maintains its structural integrity and appearance throughout its operational life.

Manufacturing Quality Control Process

Our quality control begins before production starts. Pre-production inspections verify that all raw materials meet specifications and that manufacturing equipment is properly calibrated. This proactive approach prevents quality issues from entering the production line.

During manufacturing, our quality control team conducts real-time monitoring at every stage. In-line quality checks ensure that each component meets specifications before moving to the next production phase. This continuous monitoring allows us to identify and correct any deviations immediately, maintaining consistent quality throughout the manufacturing process.

Seam integrity is critical for inflatable safety and durability. We employ reinforced seam technology that combines double-stitching with heat-welding techniques. This dual approach creates seams that are stronger than the base material itself. Every seam undergoes individual inspection to ensure proper formation and strength.

Anchor points and safety attachments receive special attention during manufacturing. These critical components undergo enhanced reinforcement procedures and individual load testing to verify they can handle operational stresses safely.

Testing and Validation Procedures

Before any inflatable leaves our facility, it undergoes comprehensive testing procedures. Pressure testing protocols evaluate how the product performs under various inflation levels, including stress tests that exceed normal operating conditions. These tests identify potential weak points and verify structural integrity.

Load-bearing assessments ensure each inflatable can safely support its intended capacity. We conduct both static and dynamic load tests that simulate real-world usage patterns. These evaluations verify that the product can handle the specified number of users safely and comfortably.

Safety feature validation covers all protective elements, including emergency exits, ventilation systems, and safety barriers. Each feature undergoes individual testing to ensure proper function and accessibility. We also verify that safety features remain effective throughout the product’s operational life.

Durability testing simulates long-term use through accelerated wear protocols. These tests help us predict product lifespan and identify components that may require enhanced reinforcement or design modifications.

Final Quality Assurance

Our pre-shipment inspection process serves as the final quality checkpoint. Each inflatable undergoes a comprehensive safety and quality checklist that covers structural integrity, safety features, and aesthetic quality. This final inspection ensures that every product meets our exacting standards before reaching customers.

Packaging standards protect product quality during transport. We use custom packaging solutions that prevent damage from handling, moisture, and environmental factors during shipping. Our packaging process includes protective materials and clear handling instructions to ensure products arrive in perfect condition.

Documentation and certification accompany every inflatable we manufacture. Each product includes quality certificates, compliance records, and detailed specifications. This documentation provides customers with confidence in their purchase and supports regulatory compliance requirements.

Batch testing records ensure complete traceability throughout the manufacturing process. We maintain detailed records of materials, testing results, and quality inspections for every product. This comprehensive documentation system allows us to track performance and continuously improve our processes.

Ongoing Support and Maintenance

Quality control extends beyond manufacturing to include proper installation and maintenance guidance. We provide detailed installation guidelines that ensure optimal safety and performance. These instructions cover site preparation, proper setup procedures, and safety considerations for different environments.

Regular inspection recommendations help customers maintain their inflatables in peak condition. We provide maintenance schedules and inspection checklists that identify potential issues before they become safety concerns. This proactive approach extends product life and maintains safety standards throughout the operational period.

Our lifetime support commitment means customers can rely on ongoing assistance throughout their inflatable’s service life. Whether you need technical guidance, maintenance advice, or troubleshooting support, our team remains available to ensure your continued success.

Replacement part availability ensures long-term durability support. We maintain inventory of critical components and provide repair kits for common maintenance needs. This comprehensive parts program helps customers maximize their investment while maintaining safety standards.

Why Quality Control Matters for Your Business

Customer safety and trust form the foundation of successful inflatable businesses. When customers see the quality and attention to detail in your equipment, they develop confidence in your operation. This trust translates into repeat business, positive reviews, and valuable word-of-mouth referrals.

Insurance and liability benefits result from using high-quality, compliant equipment. Insurance providers often offer better rates for businesses using certified equipment that meets industry standards. Additionally, comprehensive quality control reduces liability risks by minimizing the potential for safety incidents.

Long-term cost savings make quality inflatables a smart business investment. While premium products may cost more initially, their durability prevents frequent replacements and reduces maintenance expenses. Quality inflatables maintain their appearance and functionality longer, protecting your business image and profitability.

Competitive advantage comes from offering superior quality equipment. In a crowded marketplace, quality differentiates your business from competitors using inferior products. Customers increasingly recognize and value quality, making it a powerful marketing advantage.

Your Partner in Safe Entertainment

At Minye Fun, we believe that exceptional quality control is non-negotiable. Our comprehensive approach covers every aspect of inflatable manufacturing, from material selection to final inspection. We don’t just meet industry standards – we exceed them to provide you with products that deliver safe, reliable entertainment for years to come.

Our commitment to ongoing excellence means we continuously evaluate and improve our processes. We invest in new technologies, training, and equipment to maintain our position as a quality leader in the inflatable industry. When you choose Minye Fun, you’re partnering with a manufacturer that shares your commitment to safety and quality.

Whether you’re planning a single event or building a rental business, we’re here to help you succeed. Our team of experts can guide you through product selection, customization options, and operational best practices. Contact us today to discover how our quality-focused approach can benefit your business and provide peace of mind for every event.

Quality control isn’t just what we do – it’s who we are. Trust Minye Fun to deliver the safe, durable inflatables that make every celebration memorable for all the right reasons.